Cedarapids IP 1516 Impact Crusher Power Volume Control With its large feed opening, large capacity and high reduction ratio, the ® Cedarapids 1516 horizontal shaft impactor delivers extraordinary crushing power, plus high production volume Increased tip speed gives a finer product gradation Increased tip speed reduces rotor throughput Increased tip speed increases the power consumption per tonne of rotorSANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

19 行· 2016年4月15日· Crusher manufacturers publish grid charts,Horizontal Shaft Impact (HSI) crusher primary range has been designed to increase the crushing process productivity thanks to its high reduction ratio Usually utilized in the first® NP Series™ Horizontal shaft impact (HSI) crushers

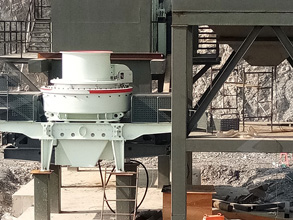

Using an impact crusher instead of a jaw or cone crusher increases the amount of fines produced If you are already using an impact crusherSandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption The autogenous "rock on rock" crushing technique results in several majorStationary VSI impact crushers, Sandvik VSI Crusher

The beauty of impact crushers is their versatility in terms of input material and output size There are many different designs out there but generally speaking impact crushers can produce material from 3" down Theimpact crusher The table below offers an indication of how adjustments to your NP Series™ impact crusher affect power consumption, product gradation and productApplication guide ® NP Series™ impact crusher wear parts

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with theHorizontal Shaft Impact Crusher Gradations Gradation Control Based on Rotor Tip Speed Andreas 4230, 4233, 4240, 4250, 52603, 52604 Andreas 4230, 4233, 4240, 4250,HORIZONTAL SHAFT IMPACTOR Model 4250 Spec Sheet

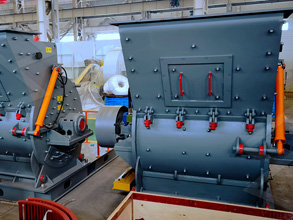

Impact crusher & impact mill (PB & PM) Impact crushers and impact mills (HSI) are universal and, at the same time, economical solutions The BHS impact crusher achieves very high crushing ratios in both the first and second stage This results in a wide range of salable, cubical final products The impact crusher can be repurposed into an impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cuft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour The compound crusher was developed to avoid the problems and the investment of a closedcircuit operationIMPACT CRUSHERS

gradation characteristics as results are shown in table3 From the gradation characteristics of particle ranging from 75mm to 0075mm (base course) It is identified that lower gradation has more wide spread range of particles comparatively middle gradation, where as upper gradation has limited range of particlesJAW or IMPACT, Open or Closed Circuit, Customize your REBEL CRUSHER to be the PERFECT FIT for you! HUGE FEED OPENING with MASSIVE HP in a COMPACT PACKAGE! Quiet and Burns LESS FUEL A “SWISS ARMY KNIFE CONCEPT” LOADED with FEATURES! ABLE to TACKLE ANY JOB! DESIGNED from Customer INPUT toThe Rebel Crusher Crush, Screen and Track RR Equipment

PRODUCT DESCRIPTION The HTI series was designed for the economic tertiary crushing of hard rock It’s a modular system, manufactured with the objective of fulfilling every task in the bulk materials industry The machine’s fittings, as well as its control, may be adapted to suit operators’ individual requirements – including fullyPRIMARY IMPACT CRUSHER / TECHNICAL SPECIFICATIONS metric; imperial; MPI 1111: MPI 1012: MPI 1114: MPI 1313: MPI 1515: MPI 1620: Rotor Diameter (mm) Rotor Diameter (inch) 1100 43: 1100 43: 1100 43: 1300 51: crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material,Primary Impact Crushers – MEKA

2015年10月28日· The output gradation of the primary HSI crusher is generally coarser than the primary breaker due to the lack of expansion above the rotor, which also affects the capacity Primary HSI crushers are considerably wider than primary breakers at comparable capacity ratings Secondary horizontalshaft impact (HSI) crushersHorizontal shaft impactors (HSI) offer the adaptability and capacity required to meet producer expectations With three or fourbar configurations, large feed opening and highperformance MPR rotor, Astec impact crushers are wellsuited for a variety of applications With 30% more uptime and 25% more production than competitive models, ourHorizontal Shaft Impactors Astec

Product gradation curve values are estimated depending on feed material density and crushability, rotor speed, installed power, and with new installed blow bars Tonnage values are estimated depending on feed material size & gradation curve, rock crushability, material density, installed power, and proper crusher setting Primary (Top feed size =® NP13 & NP15 Impact crushers The new NP13 and NP15 impact crushers provide significant improvements for your productivity, safety and uptime NP13 & NP15 offer minevik's latest innovations for quick, easy and safe maintenance More throughput, less recirculation The NP13 and NP15 impact crushers have been® NP13 & NP15 Impact Crusher Brochure

2021年12月9日· Impact Crushers produce the most uniform cubical shape for finished products, due to its consistent ability to uniformly break apart aggregates through striking Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft ImpactorThere are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top ofCrushers All crusher types for your reduction needs minevik

Dec 02, 2017· •Three main crusher types: jaw, cone, and impact –Tell contractor desired gradation/result –Contractor to select crushing process for desired gradation and material properties 19 0 20 40 60 80 100 01 1 10 100 % Korngröße / mm Backenbrecher Prallbrecher Impact Jaw Crusher Particle size, mm singThe APK Secondary Impact Crusher is equipped with our latest generation and industry exclusive technology, the HAZtronic Control System This stateofthe art apron control system offers a level of impactor performance and operational technology that ensures the production of a high quality, consistent product gradationAPK | Secondary Impactor | Hazemag North America

If you are already using an impact crusher you can work on your impact crusher settings to get the aggregate gradadtion right Rotor Speed: The rotor speed or (the speed at the tip of the hammers / tip speed) affect the intensity of the pulverization The higher the rotor speed the higher the impact and the finer the end product2002年10月1日· Abstract and Figures In this paper we develop a performance model for impact crushers The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity(PDF) A performance model for impact crushers ResearchGate

Impact Crusher Gradation Chart curacyte impact crusher gradation chart machinery offers crusher and grinder plant for mineral quarrying,crushing,dressing,recycling with the excellent More Details Crusher Feed Gradation Grinding Mill China what is gradation in a models developed using crusher tests dynamically change the crusher2021年3月25日· Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more Using a combination of impact, shear and attrition reduction methods,McLanahan | What Type of Crusher Is Best for Primary Crushing?

Just call +903123979133 and we will help you in any way we can You can also send an email to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information Use the Call Back option if you would like to be contacted by our sales team MVIG Series vertical shaft impact crushers areNP impact crusher components The main components of the NP Series™ impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates Small mobile machines (NP1110™ and NP1213™) have only one breaker plate NP Series™ impact crusher basic concepts NP Series™ model Feed opening Maximum feed size Maximum installed powerApplication guide ® NP Series™ impact crusher wear

Impact Crusher is equipped with our latest generation and industry exclusive technology, the HAZtronic Control System This stateofthe art apron control system offers a level of impactor performance and operational technology that ensures the production of a high quality, consistent product gradation We call it Intelligent Crushing!If needed, readjust your closed side setting, and verify that the crusher housing is locked properly Check how this is done here Check if the rotor moves freely by turning the pulley 2 Clean Your Screens Remove any material pegging and blinding the prescreen to allow a smooth material bypass Similarly, clean the screen attachmentImpact Crusher Maintenance Guide | Your Daily Morning Routine

NP impact crusher components The main components of the NP Series™ impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates Small mobile machines (NP1110™ and NP1213™) have only one breaker plate NP Series™ impact crusher basic concepts NP Series™ model Feed opening Maximum feed size Maximum installed powerIMPACT CRUSHERS (VSI) CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are designed for higher capacity, Product gradation is further controlled by the rotational speed of the rotor and /or the quantity (percentage) of BiFlow® usedSANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

Portable Tertiary Impact Crushers are wheelmounted rock crushing machines, engineered for tertiary crushing applications Equipped with a horizontal shaft impact crusher and a feed hopper with belt feeder, it is designed especially for processing soft and mediumhard materials, such as limestone and recycled materials, and ideal for theThe GS series crusher’s bearing seat uses a thin oil lubrication system Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operationsVertical Shaft Impact Crusher AF Minerals Equipment

VERTICAL SHAFT IMPACT CRUSHER INNOVATIONS FOR BETTER CRUSHING BIFLOW™ The hexagonal BiFlow hopper with BiFlow ports and BiFlow Collection plates enables perfect, controlled feed material flow It enters the crushing chamber in the opposite direction from material leaving the rotor The operator can adjust gradation and output2023年2月9日· Gradation in a crusher refers to the distribution of the size of the crushed material produced by the machine A wellgraded material will have a balanced distribution of particle sizes, meaningWhat is gradation in a crusher? LinkedIn

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers and a major cost driver The purpose of blow bars is to strike material entering the crushing chamber and throwing it against the impact wall causing the material to fracture into smaller particles (see also: how does an impact crusher work)In the64 x 118 (1600 x 3000) 123,600 (56,2000) Contact Us The HPIH Primary Impact Crusher is ideally suited for crushing mediumhard rock down to a well graded product size of 0 – 6 inch Due to its operational flexibility, economical operation and excellent product size control, this machine is the top choice for the North AmericanHPIH | PRIMARY IMPACTOR | Hazemag North America

Cedars 5064 HSI Crane Specifications, Load Charts, and Crane Manuals are for *Reference Only* and are not to be used by the crane operator to operate any type of crane, telehandler, lift truck or aerial access device To obtain OEM Crane Service, Crane Parts or Crane Maintenance Manuals, contact the crane and or lifting manufacturer directlySince 1991, RUBBLE MASTER has brought numerous innovations to the market We’re crushing & screening experts and work closely with contractors and aggregate producers worldwide Many contractors needRM 100GO! Tracked Impact Crusher | RUBBLE MASTER

2021年9月2日· 11 Impact crushers can be divided into two types according to the number of rotors: singlerotor and doublerotor impact crushers 12 The structure of the single rotor impact crusher (Figure 1)For material weighing 16 t/m³ or 100 lbs/ft³ Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit designVertical Shaft Impact Crushers – L Model– MEKA

impact crusher ekiti An impact crusher is a stone pulverizer machine that strikes materials, such as cement, rock, minerals, etc, to pulverize it and to create a finished product Buying an impact crusher is a costefficient alternative to impact crusher rental or buying new We offer multiple ways to buy a horizontal impact crusher: liveImpact Crusher is equipped with our latest generation and industry exclusive technology, the HAZtronic Control System This stateofthe art apron control system offers a level of impactor performance and operational technology that ensures the production of a high quality, consistent product gradation We call it Intelligent Crushing! Secondary Impactor | APS, APSM

2023年9月4日· To improve the quality of reclaimed asphalt pavement materials (RAPs) and reduce the variability of RAPs, a refined decomposition process was applied to treat RAPs The change rule and variability of aggregate gradation, asphalt content, aged asphalt properties and aggregate (extracted) properties of RAPs were analyzed with differentNP impact crusher components The main components of the NP Impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates In small mobile machines (NP1110 and NP1213), there is only one breaker plate Wear parts application guide NP series impact crusher NP impactor and basic concepts Breaker plates Side liners Blow NP series impact crushers Wear parts application guide

Horizontal impact crusher and impact crushing plant to suit Horizontal shaft impact crusher bettershaped product Hammers have four crushing positions to maintain a more constant gradation and greater top size controlHorizontal Shaft Impact Crusher Gradations Gradation Control Based on Rotor Tip Speed * Capacity depends on feed size and gradation, type of material, etc Andreas 4230, 4233, 4240, 4250, 52603, 52604 Feed Gap Speed 6500 5000 6500 5000 6500 5000 Sieve Size 3" 100 100 2 1/2" 96 100 100 93 2" 100 93 100 95 93 86 1 1/2" 96 90 94 88 85 80HORIZONTAL SHAFT IMPACTOR Model 4250 Spec Sheet