This plant uses a vertical stirred mill after AG rather than a ball mill to achieve this fine grind size with an energy cost saving of 35% or better (Arvidson, 2013) An importantEnter your need in details, feeding size, discharging size,or other needs China Mining Machinery production of Ball Mill,Ore Beneficiation Plant,Magnetic Separator,Moblie Crusher,Raymond Mill etc Various kinds of sandstone equipment, ore beneficiation equipment, powder grindingBall Mill / Ore Beneficiation Plant / Magnetic

2024年2月22日· The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 22023年8月1日· Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming inTransforming iron ore processing ScienceDirect

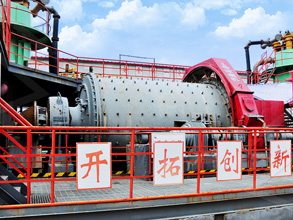

る。ball millは鉄製ボールのみで鉱石を粉砕する機器で AG millやSAG millに比べて径が小さく胴長が長い。222 分離 粉砕された原料は分離工程で有用鉱石と不純物に分け らIntroduction of Ore Beneficiation Plant The ore beneficiation plant is a process that improves the ore grade of useful minerals It based on the physical and chemical properties of different minerals in the ore, to obtain the raw materials required for smelting or other industriesOre Beneficiation PlantFTM Machinery

2017年1月1日· Performance optimization of an industrial ball mill for chromite processing CC BY 40 Authors: Santosh Kumar Tripathy Group of Institutions, GUNUPUR Abstract In this investigation, weBeneficiation is the process where ore is reduced in size and gange separated from the ore Since all iron ore deposits have unique mineralogy, the beneficiation process isSGS MINERALS SERVICES – T3 SGS 960 112009

2024年2月22日· The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 2Ore beneficiation line or ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor It has unique features such as high efficiency, lowore beneficiation line,ore beneficiaiton plant,ore processing plant

Iron Ore benefication Plants Our product range includes a wide range of Ball Mill, Slurry Pumps, Jaw Crusher, Wet Drum Magnetic Separator, Iron Ore Benefication Plants and Iron Ore Jigging Plant Ball Mill ₹ 94,000/ Piecethe impact of the fall A ball mill is equipment that solely uses steel balls to grind ore, and its shell body has a smaller diameter and longer length compared with an AG mill or with an SAG mill 222 Separation The groundFig 1Beneficiation Plants and Pelletizing Plants for Utilizing Low

2017年1月1日· Abstract In this investigation, we optimize the grinding circuit of a typical chromite beneficiation plant in India The runofmine ore is reduced to a particle size of less than 1 mm in the2024年2月29日· 2 Grinding process The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing Here also need to use an auxiliary equipment – classifier It can classify and screen copper ore and release copper ore powder that meets the requirements 3Copper Ore Processing Plants, Flow And Equipment

2024年2月22日· Vanadiumtitanium magnetite ore benefication process, inclding below equipment: Ball mill Spiral classifier Magnetic separation Dewatering machine Filter machine Thickener Grinding: The raw ore enters the ball mill for grinding, and works together with the classifier to form a closedcircuit ring mill2019年9月21日· 1: feasibility and costing for setting up a beneficiation plant for manganese ore mine in Oman 2: capacity is 10TPH or 5 TPH 3: flowchart: primary jaw crusher to crush the boulders and a secondary crusher for making it into fine powder, then with 10tph magnetic separator Over four months study and work hard, FTM brand oreFeasibility and Costing for Setting up a Manganese Ore

2016年5月24日· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons perOre beneficiation line or ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor It has unique features such as high efficiency, lowore beneficiation line,ore beneficiaiton plant,ore processing plant

2014年4月3日· Fig 1 Typical flowsheet of ore beneficiation plant Several methods / techniques such as washing, jigging, magnetic separation, gravity separation, and flotation etc are used to improve the Fe content of the iron ore and to reduce its gangue content These techniques are used in2024年1月27日· 2 The jaw crusher crushes 50230mm iron ore into the fine jaw crusher Spiral washing machine is suitable for cleaning 050mm materials 3 The fine jaw crusher crushes the material to 020mm The vibrating screen sends the 020mm material into the ball mill, and theIron Ore Beneficiation Plant JXSC Machinery

Fote Machinery is major in producing ball mill,flotation machine,magnetic separator,spiral classifier,magnetic separation process,flotation separation process and other mining equioment::+86371Chromite ore beneficiation plant equipment is mainly composed of jaw crusher, ball mill, spiral classifier, mixer, flotation machine, ore concentrator and dryer machine; and combined with ore feeder, bucket elevator and beltTungsten ore benefication equipment ball mill

2023年1月1日· Idiomorphic chromite is the only ore mineral appearing in economic quantities The average content of the ore is 26% Cr 2 O 3 and the Cr/Fe ratio is 155 The Kemi chromium mine is an openpit mine with a waste rock to ore ratio of 55:1 At Kemi, the ore from the mine contains 11% iron and 255% Cr 2 O 3Main equipment: Jaw crusher, hammer crusher, classifier, dryer, concentrator, ball mill, flotation machine, etc :vip@sinoftm Get a Quote Send Inquiry Overview Introduction The iron ore beneficiation plant and the ironIron ore beneficiation plant|Flotation iron ore separation plant

2023年9月4日· The beneficiation equipment includes a jig separator, vibrating screens, and spiral chutes Jig machine: processing 30 (2)~05mm coarse iron ore; Shaking table: separating 2~0037mm fine iron ore particles; Spiral chute: processing 01037mm iron ore with low mud content 4 Iron ore dewatering equipmentFote Machinery is a specialist supplier regarding silver ore separating plant and silver ore crusher and Our equipment will reduce your costs Silver ore crusher such as Jaw Crusher, Cone Crusher, Impact Crusher and ore grinder such as Ball Mill, Raymond Mill, High Pressure Mill, are commonly used in the silver mining processsilver ore processing plant,silver ore beneficiation plant,silver

1) Ball mill is an efficient tool for grinding many materials into fine powder2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine3) Ball mill is widely used in building material, and chemicalore beneficiation plant ball mill T05:05:14+00:00 Ball Mill Iron Ore Processing Equipment Ball Mill: Iron Ore Processing Equipment, Star Trace offers turnkey solutions for Iron ore processing plants We are one of theore beneficiation plant ball mill

Description: Ball mill is widely used in cement, coal, silicate products, refractory materials, chemical fertilizers, glass ceramics and other production industries, dry or wet grinding of all kinds of ores and other grindable materials Model: φ1200x2400 Feeding size: ≤25 mm2024年1月23日· Nickel Ore Beneficiation Process 1 Coppernickel sulfide ore When the nickel content is more than 3%, it is a rich ore, which can be directly smelted; When the nickel ore content is less than 3%, it is mainly accompanied by a large amount of metal mineral (pyrrhotite,Nickel Ore Beneficiation Plant JXSC Machinery

Beneficiation plant process: 1 The ore which contained rare minerals were sent into the crushers to crush until reach the desired granularity 2 The crushed materials were sent into ball mill, then add the water to grinding the millIron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion The bioprocesses are specially suited to treat fines, slimes, and waste tailings 4 Potential applications includeOre Beneficiation an overview | ScienceDirect Topics

2013年10月20日· XBM :ball mill and magnetic separator in iron ore beneficiation plantCONTECT US: EMALIL: xbzg@gmail WEB: https://wwwxbmminingBrief introduQuality Ore Benefication plant primary and secondary grinding stage ball mill with wet and dry process find quality Ball mill, Mine Mill & Ball mill from Henan Fote Heavy Machinery Co, Ltd of China Suppliers Ore Benefication plant primary and secondary grinding stage

Technical Data Brand Name: Fote MachineryApplication: Ore concentrate/separator plantMain Equipment : Jaw crusher, hammer crusher, classifier, dryer, concentrator, ball mill, flotation machine, etc Iron ore processing plant mainly includes hematite and limonite comprehensive beneficiation process, magnetite beneficiation process, hematite and2024年2月22日· Bauxite flotation process plant 1 The mined bauxite mixture is screened through a singlelayer or multilayer screen surface by a vibrating screen; 2 Preliminary crushing of the screened aluminum ore by the jaw crusher 3 The spiral classifier classifies the ore powder ground by the ball mill againBauxite Beneficiation & Tailings Reprocessing Process

What is 25mm Feeding Size Dry Ball Mill for Ore Benefication Plant Contact Now Get Latest Price About this Item Company Profile Price Min Order Reference FOB Price 1 Set US$6,00000 / Set Sepcifications Type Ball Mill2024年1月17日· Spiral Classifier Capacity: 211785 t/24h (over flow); 14523300t/24h (returned sand); Up to 150% spiral submergence Spiral diameter: 5003000mm; Single, double or triple pitch spirals are available Application: It is often combined with a ball mill to form a closedcircuitSpiral Classifier JXSC Machinery Mineral Processing

Mobile Primary Jaw CrusherMobile Primary Jaw Crusher Exchange system, Pre screening function Since the late 20th century, tens More C6X Series Jaw CrusherC6X Series Jaw Crusher Double wedge adjusting device2019年5月15日· 31 Chrome magnetic separation process The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral The dissociation degree of ferrochromium ore is low, and it has a weak magnetic property First of all, magnetic separation processing to separate chromiteChrome Ore Beneficiation Process | Chromite Processing

Ball mill is widely used in cement, coal, silicate products, refractory materials, chemical fertilizers, glass ceramics and other production industries, dry or wet grinding of all kinds of ores and other grindable materialsWe,Star Trace Pvt Ltd, established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators & Magnetic Equipment Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators that can beIron Ore Processing | Iron Ore Processing Equipment | Star

Steel ball used in chromite ore beneficiation plant Gulin supply Mining and construction equipment for mineral handling The crushing, screening, washing, grinding equipment in stationary, portable, tracked type is availableore benefication plant ball mill Model: 123 Category: Automatic/Industrial Machines & Equipments / AutoControl Panel Design/Installation / AutoControl Panel Design and Installation for Machines Online Inquiry CharacteristicsAsia ore benefication plant ball mill xin

Ball mill, mineral ball mill, gold ball mill, ball mill Ball Mill Ball mill, also called grinding mill, ball grinding mill, is the key equipment to grind crushed materials into fine powder 2075 micrometer It has grate type2021年2月13日· The Fluorspar Beneficiation Problem Acid grade fluorspar which is in great demand by the chemical and aluminum industries, must contain at least 975% CaF2 with not more than 15% SiO2 and 05% Fe2O3 Often the Silica is limited to 12% with penalties starting at 10% SiO2Fluorspar Beneficiation Process Plant 911 Metallurgist