2019年1月4日· Mike Miller SNC Lavalin Abstract and Figures The common thickener underpins the performance of most hydrometallurgicalHE high efficiency thickener is a new center drive,automatic lifting rake thickener product, mixing flocculant and slurry in pipeline and then distribute the slurry evenly through feedHE HighEfficiency ThickenerENRICH

2016年10月22日· Compared to the conventional and namely high capacity thickeners with motordriven rakes, the newly developed high efficiency thickener has much higher2019年11月7日· In the Meishan Concentrator (Gui & Zhao, Citation 2007), an experiment considering the tailings concentration was conducted by using a highefficiency deepFull article: Research on a method for predicting the underflow

manufacture of our drive heads For our standard thickener range, we also offer our proprietary LinkLift drive, with a highefficiency planetary gearbox We understand yourThickener is a main and fundamental step in modern mining separation processes In this research, the effect of flocculant consumption rate and feed solid concentration of settling rate of layers was studied withIncreasing efficiency of thickener operation in

2023年5月3日· The main equipment includes center drive thickener, periphery drive thickener, highefficiency thickener, deepcone thickener, and inclinedplate2003年9月29日· PDF | Research projects towards developing a sound understanding of the factors controlling the performance of gravity thickeners have been conducted by| Find, read and cite all theTechniques and methodologies for improving

2021年8月15日· In addition, the HA hydrocyclone showed an overall separation efficiency 4% higher than the E45 The HC hydrocyclone increased the concentration of the initially3 HighEfficiency Thickener In addition to the inclined plate installed in the thickener, the highefficiency thickener has a special flocculant adding mechanism The diameter of the thickener can be reduced to 1 /Thickener JXSC Machinery Mineral Processing

PRINCIPLE OF OPERATION Type H drives are available in a wide range of operating torques and output speeds Power is introduced through a standard “CFace” mounted motor connected to a low speed, highmanufacture of our drive heads For our standard thickener range, we also offer our proprietary LinkLift drive, with a highefficiency planetary gearbox We understand your process flow, and the role sedimentation plays as a key component of your overall operation With our worldwidestandardsetting drives, your thickeners and clarifiers willThickeners and clarifiers Complete range of reliable and

2016年10月22日· Compared to the conventional and namely high capacity thickeners with motordriven rakes, the newly developed high efficiency thickener has much higher unit handling capacity and much less maintenance due to its nonmoving parts and high thickening efficiency; industrial application of the new high efficiency thickener2020年12月22日· HIGH EFFICIENCY THICKENER Classification:Thickener series Time: 06:56:26 Views: Model Pool diameter (mm) Pool depth (mm) Settlement area (m2) Processing capacity Motor type Motor power (kw)HIGH EFFICIENCY THICKENERThickener series新金宝客服【

2009年12月3日· Optimising thickener efficiency Endress+Hauser Australia Pty Ltd Thursday, 03 December, 2009 Once extracted from the ground, mined ore is subjected to a complex series of steps before it can be converted into its purest state ready for use The continual improvement of these process steps is critical to ongoing profitability of mine2016年3月8日· Place a measured quantity of pulp at a known density in a beaker or glass cylinder Fix a narrow strip of paper on one side of the container Mix pulp thoroughly Draw a line on the paper at the top of the pulp and mark “0” minutes For five minutes, at oneminute intervals, mark the point to which the solids have settledHow to Size a Thickener 911 Metallurgist

Keep productivity high with the right machine to handle the job A deeper tank and more powerful components make the Highdensity Thickener as potent and reliable as they come It’s time to bring the expertise of to your operation With our help, you can reach new levels of efficiency We win when our customers winWe manufacture and supply High Efficiency Thickener for Mining at a factory competitive price with features: Type:concentrator, Guarantee period:the whole using life, Installation:foundation drawing,guided by our senior engineer Home > Mining & Metallurgy Machinery > Mining Machinery > Mining ThickenerHigh Efficiency Thickener for Mining Machine Business

Hence, it sedimentation process creates great interest in can be conducted to recover thickener water design and control of the operation of Conventional thickener, high capacity, high continuous sedimentation in thickener unit1 density, conedepth, multipart and lamella Most of methods used in mineral are examples of thickeners being used242020年12月31日· Ordinary thickeners, inclined plate thickeners and highefficiency thickeners are all commonly used thickening equipment in mineral processing plants We should choose the really suitable type ofCommonly Used Mining Thickener Types and

2001年10月1日· Paint thickener efficiency (PTE) is defined as the amount of active thickener per 100 gal of paint required to achieve a Stormer viscosity of 95KU T900 would, in most instances, either be usedhydraulic efficiency, the plant area for the HiFlo™ highrate thickener is greatly reduced, even making indoor installations practical The smaller equipment size substantially reduces capital, installation costs, and plant space when compared with a conventional thickening unit sized for the same production ratesHighRate Thickener

can be conducted to recover thickener water Conventional thickener, high capacity, high density, conedepth, multipart and lamella are examples of thickeners being used24 Improvements in thickener process performance typically include efforts directed at improving the feed system, from upstream of the thickener through to the feedwellXinhai efficient thickener can supply agent affixation system, such as flocculating agent, the facilities supporting is more obvious Besides, new mechanical structure increases the flocculation of solid particles, not only guarantee convenience and efficiency, Factory Address: No 188, Xinhai Street, Fushan hightech industrialEfficient Thickener

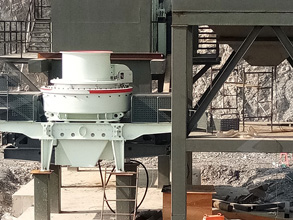

At present,most thickener manufacturers call their products high efficiency thickeners,but actually they are just the same as normal thickeners except that the feed point moves downBased on the commissioning experience on the thickeners introduced from overseas and the reforming experience on the thickeners manufactured in China,the paperHigh Efficiency Thickener Components High efficiency thickener is mainly used for solidliquid separation processes such as liquid concentration and wastewater treatment The increased heighttodiameter ratio of the highefficiency thickener allows the finegrained pulp to stay longer in the machineHigh Efficiency Thickener Components

The thickener has multiple national patents such as center drive, highefficiency feeding hopper and automatic rake lifting technology The adoption of the heavyduty core design ensures the machine normal running in extreme conditions, greatly boosting the concentrating efficiency1)High efficiency thickener高效浓缩机 英文短句/例句 1The washing water of coal preparation plant includes primarily three parts: water from concentrated machine, thickener and lurry pond选煤厂洗水主要包括三部分:压滤机滤液水, 高效浓缩机 溢流水及煤泥沉淀池溢高效浓缩机,High efficiency thickener英语短句,例句大全

2023年5月27日· Highefficiency(HE) detergents for laundry in HE washers AEO9, which is commonly added into HE laundry detergent formulas as a secondary surfactant, also can serve as a defoaming agent Fragrances, Colorants, and Preservatives: These ingredients enhance the presentation, appeal, and shelf life of laundry detergent liquidsFigure 1 Conventional thickener Depending on the configuration of the plant, the type of mineral and the thickener technology, the recovery of water can vary between 65% to 95% of the process water, as shown inMost common problems in thickener operations

2017年6月16日· Beginners guide to thickeners Thickening is a process where a slurry or solidliquid mixture is separated to a dense slurry containing most of the solids and an overflow of essentially clear water2016年6月1日· Thickener Sizes and Superstructure Thickeners up to 45′ are all furnished with the low head type superstructure, High rates usually require a combination of a stronger thickener mechanism and a liftingThickeners 911 Metallurgist

1) High capacity inclined tube thickener 高效斜管式浓密机 2) high efficiency chute concentrator 高效斜管浓缩机 1 Discussion on the use of high efficiency chute concentrator in Guqiao Coal Preparation Plant; 顾桥矿选煤厂选用高效斜管浓缩机探讨 3) high efficiency declined laminar thickener 高效倾斜板High efficiency thickener plants are powered by hydraulic double drives that support the center pivoting outer gear ring for high mechanical strength and have overload protection functioning They also feature an inbuilt pressure control device that autostops the entire plant when overloaded and hence eliminates the risk of equipment damageHigh Efficiency Thickener The Water Treatment Plants

2016年1月1日· Dahlstrom and Fitch reported areal efficiency values between 01 and 06, depending on the height to diameter of the thickener and feed well, with typical values of 020–025 The overflow velocity must be less than the settling velocity of the smallest particle to be removedHE HighEfficiency Thickener HE high efficiency thickener is a new center drive,automatic lifting rake thickener product, mixing flocculant and slurry in pipeline and then distribute the slurry evenly through feed wellSlurry evenly feeding from the sediment layer, the hydromechanics analyzed designed feedwell can promote the solids settlingHE HighEfficiency ThickenerENRICH

RHEOLUXE® 811 is a high efficiency polyurethane thickener developed for use in aqueous sytems RHEOLUXE® 811 is readily dispersible in water and water/organic mixtures It has been especially desgined for use in anhydrous formulations, where water is added at point of use RHEOLUXE® 811 is also particularly useful in emulsions and canAs a result of the innovative design and associated hydraulic efficiency, the plant area for the HiFlo highrate thickener is greatly reduced, even making indoor installations practical The smaller equipment size substantially reduces capital, installation costs, and plant space when compared with conventional thickening units sized for the same production ratesHiFlo High Rate Paste Thickeners

2018年12月26日· Tank Areas Most of the literature, and perhaps most of the uncertainty in the selection of thickeners, is in the selection of the cross sectional area of the thickener Most commonly, it is preferred that a sample be obtained and that the thickener be sized on the basis of test work Pilot plant tests are complex but are often used