62 Flotation Machine Upsizing Technology 181 621 TankCell Flotation Machine 182 622 Wemco Flotation Machine 71 SF, BF and GF Mechanical Agitation2019年10月31日· Flotation which has significant usage area in mineral processing is starting to gain a new role in a wide range of studies with(PDF) Developments in Flotation Technology ResearchGate

2010年10月1日· In this paper, two new technologies are described, one to improve the flotation kinetics of ultrafines, and the other to extend the upper limit of flotation byEFD has developed two distinct technology platforms based on this twostage flotation concept, the StackCell and the Tank Feed Air Jet Figure 2—A cutaway of theNew Technology and Applications for Flotation through

2010年10月1日· If these aims can be achieved, there will be obvious gains in plant efficiency and productivity In this paper, two new technologies are described, one toOur technology Customer stories Improve your plant’s performance with our flotation solutions The performance of your flotation circuit is essential to your production EvenProductive froth flotation technology |

2021年3月14日· The flotation machine upsizing technology is the core secret of flotation machine manufacturers This section will briefly introduce the upsizing technology of2022年4月1日· The Recent advances in Inc as a pioneer company in flotation processes can be classified into three groups: i) forcedair flotation machines (DorrTechnological assessments on recent developments in fine and

2021年3月14日· The flotation process control is an important method used to improve the flotation efficiency Since the 1940s, the process control technology of flotation2016年11月4日· The future of flotation Buoyed by pressure to cut costs and improve recovery, new flotation technologies are on the rise By Eavan Moore November 04, 2016 Woodgrove Technologies’ stagedThe future of flotation Canadian Institute of Mining,

2023年7月31日· A further increase in the hydrodynamic parameters resulted in a decline in recovery Hydrofloat outperformed the conventional Denver flotation machine across the following size fractions: +106 − 150 µm, +150 − 年3月14日· Flotation is a complex physicochemical reaction process involving the three phases of gas, liquid and solid The scaleup process of the flotation machine does not mean to increase geometric dimensions of key components (such as the tank cell, rotor and stator) of the flotation machine simply in proportion, but it requires the fullFlotation Machine Upsizing Method and Technology

2018年3月15日· 1 Introduction Froth flotation is one of the primary mineral processing approaches for separation and upgrading of valuable minerals from their ores (Fuerstenau et al, 2007, Nagaraj and Farinato, 2016)In froth flotation, a collector (a kind of surfactant) selectively attaches to a target mineral using its minerophilic group (Somasundaran andNew technology and equipment for flotation of potassium ore, 11th International Congress of Mineral Processing, Cagliari, Special volume p 199, Ente Mineratio Sardo, Cagliari, Sardinia, 1975 Google ScholarEngineering Aspects of Flotation in the Minerals Industry: Flotation

62 Flotation Machine Upsizing Technology 181 621 TankCell Flotation Machine 182 622 Wemco Flotation Machine 71 SF, BF and GF Mechanical Agitation Flotation Machines 214 711 SF Flotation Machine 214 712 BF Flotation Machine 216 713 GF Flotation Machine2010年10月15日· @misc{etde, title = {New directions in flotation machine design} author = {Jameson, G J} abstractNote = {The theoretical background for flotation kinetics of ultrafine and coarse particles are explored Recent advances in flotation technology for these difficult areas are reviewed, with a focus on improving the flotationNew directions in flotation machine design OSTIGOV

This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral processing techniques Over 90% of the nonferrous minerals and 50% of the ferrous minerals in the world are treated using flotation: a complicated technique including procedures from2021年3月14日· 12122 Application of Flotation Machines in Wunugetushan Copper–Molybdenum Mine The Wunugetushan Copper–Molybdenum Mine is a new large copper mine built in 2008 Basic flotation circuits: The raw ores are grinded and classified to obtain the mixed copper–molybdenum concentrate after bulk flotationApplication Examples of Flotation Machines | SpringerLink

1999年4月1日· The significance of deinking technology is mirrored in the development of deinking capacities which rose from 15 million to 59 million t/year worldwide in the years from 1972 through 1981, and which then further increased almost 3fold in the following 10 years (Fig 1)There are currently approximately 600 major deinking systems either2010年10月1日· A new cell has been developed, the Concorde Cell, in which the preaerated feed is raised to supersonic velocities before passing into a highshear zone in the flotation cell The localNew directions in flotation machine design ResearchGate

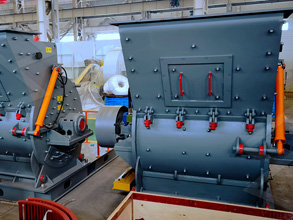

There are roughly 40,000 WEMCO flotation machines installed around the world, according to , and the new WEMCO II, shown here, offers improvements in power consumption, air flow and pumping introduced two developments in their flotation portfolio — the WEMCO II and the REFLUX Flotation Cell (RFC) — at the2011年9月14日· It is hoped that this will change as a result of the development of new technologies such as machine vision and the measurement of new control variables, such as air recovery This review looks at each of the four essential levels of process control (instrumentation, base level flotation control, advanced flotation control and optimisingA review of froth flotation control ScienceDirect

2021年3月13日· This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral processing techniques Over 90% of the nonferrous minerals and 50% of the ferrous minerals in the world are treated using flotation: a complicated technique includingExperimental Study on the Design of New Jet Vortex Flotation Machine Min Fanfei, Fei Zhikui, +4 authors Wang Chao Published 2016 Engineering No Paper Link Available Save to Library Create AlertExperimental Study on the Design of New Jet Vortex Flotation Machine

Again, the technology is not new — Eriez has been running it’s StackCell in coal applications for 15 years — but the company has recently redesigned it to handle base metals “We have a couple of base metal installations in Australia, and we think the StackCell can potentially take a big part of the market share from stirredtank2022年4月1日· 1 Introduction Froth flotation was undoubtedly the most innovative and groundbreaking discovery for mining in the 19th century (Wills and Finch, 2015)Nevertheless, it did not last long that scientists recognized its limitations for extremely fine and coarse particles, which has remained a longstanding unsolved issue in theTechnological assessments on recent developments in fine and

2021年3月14日· With the rapid progress of computer science and technology, the computational fluid dynamics (CFD) simulation technology, which has gradually emerged and developed since 1960s, makes it possible to research the flotation equipment, a kind of complex threephase mixing equipment, by the computational fluid dynamics method and2011年11月1日· For more than a century now, flotation has been at the heart of the mineral processing industry In this month’s SPOTLIGHT FEATURE ARTICLE, direct from the November issue of INTERNATIONAL MINING magazine, John Chadwick examines new technologies and applications from some of the key players in mineral flotation, aMineral Flotation International Mining

2015年6月22日· Industrial flotation machines can be divided into four classes: mechanical pneumatic froth separation column airlift matless Laboratory/Test Froth Flotation Machine As pneumatic and froth separation devices are not commonly used in industry today, no further discussion about them will be given in this module2021年1月1日· This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral processing techniquesPrinciples and Technologies of Flotation Machines

With 40,000 machines in operation around the world, WEMCO flotation devices have been the industry standard for more than 50 years The broad appeal is attributed to easier startup, simpler operation and lower reagent consumption Yet, we knew we could take an evolutionary approach and further improve the WEMCO designHence, new techniques in the fields of design, modelling, optimization, and control of flotation processes have attracted a great deal of attention This Special Issue is dedicated to the latest findings on methodologies,Design, Modeling, Optimization and Control of

2021年9月20日· In the existing designs of flotation machines, The authors propose an additive technology for layerbylayer production of an impeller on a 3D printer using the Ultimaker Cura slicer program Jameson, GJ, New directions in flotation machine design, Miner Eng, 2010, vol 23, pp 835–841Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic This is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation

Background The Staged Flotation Reactor (SFR) was developed by going back to the first principles of flotation and examining how best to optimize the various phases of flotation without preconceived constraints The result is a machine that optimizes the three stages of flotation within three separate zones, such that each zone is mutuallyNovacell Jord 360 NovaCell™ was developed by Laureate Professor Graeme Jameson and it is only available by Jord International For more information Sherwin Morgan or call +, or Shaun Wait and call +NovaCell coarse and fine particle flotation in one device | Jord

In flotation practice, mineral selectivity can be achieved through the addition of various reagents that can control the wettability of a particular mineral in the mixture in the flotation pulp Flotation reagents are commonly classified into the following categories: collectors, activators, depressants, frothers, and modifiers A significant2019年10月28日· Posted by Paul Moore on 28th October 2019 recently announced two important flotation innovations – its mixedROW™ Flotation System, which “combines the best attributes of two technologies to create nextlevel results” and the Froth Recovery Upgrade Package which finds solutions to flaws found in original froth recovery on the next level of flotation technology & innovation

Prominer can provide SF series selfpriming flotation machine and XCF/KYF series pneumatic flotation cell which are mainly used for the recovery and upgrading of sulfide ores such as cooper ore, lead & zinc ore, gold ore, silver ore, nickel ore And it can be also used in some nonsulfide ores include fluorite, graphite, quartz, tungstenIf you have any inquiries related to an existing or previous order, please contact our ongoing customer service by or phone Customer service hours are 9am to 5pm EST Monday through Friday service@hallflotation 8444235628 Shop Afloat waterbeds for your next bed and enjoy the best night’s sleep of your life Try our riskfree 100The Modern Waterbed For A Better Night Sleep | Afloat

2011年1月1日· The Australian coal industry has shown major innovation in relation to coal flotation machines Since 1990, the traditional mechanical flotation cell circuits, previously the mainstay technologyA Jameson Cell occupies much less space and delivers much more concentrate than conventional cells In fact, the recently announced Ozernoye concentrator plant, processing Zinc, will utilise just 19 Jameson Cells, rather than 63 conventional cells Not only is this reducing construction by a third, but the footprint of the plant will be lessHow Much Concentrate Would A New Jameson Cell Flotation

2014年11月7日· Design and Operation of Mechanical Flotation Machines Michael G Nelson 1 , Dariusz Lelinski 2 , and Sami Gronstrand 3 1 University of Utah Mining Engineering Department, 135 South 1460 East, Room 313, Salt Lake City, Utah, USA 2 Minerals, 2850 South Decker Lake Drive, Salt Lake City, Utah, USA 3Flotation Technologies' quality system is registered and qualified to: Achilles Joint Qualification System, First Point Assessment (fPal) and ISO 9001:2000 In 2007, Flotation Technologies moved to a new facility, significantly increasing manufacturing capacity and staff The company expanded into a 4,200 square meter facility (45,000 square feet)Flotation Technologies Inc | Hydro International

Abstract Since their first commercial application for mineral separation in the early 1980s, flotation columns have become a standard piece of equipment in mineral concentrators particularly for cleaning operations This chapter presents and discusses the most recent advances in instrumentation and automatic control of flotation columnsConsult DorrOliver Eimco's entire Flotation technology catalogue on DirectIndustry Page: 1/16 Exhibit Below is a photo of the largest flotation installation in the world consisting of 66 250m3 Wemco Flotation Machines located in Research & Development is devoted to advancing flotation with new and innovativeFlotation technology DorrOliver Eimco PDF

Flotation cell technology and circuit design—an Anglo Platinum perspective Pre 1980s—Mineral extraction circuits were characterized by multiple small flotation machines (typically 1m3) with short residence times, employing a single millfloat configuration Typically a threestage crushing, closed circuit ball mill comminution circuit2017年7月19日· March 2020 Innovations in Mineral Processing and Extractive Metallurgy have propelled civilization by creating new and improved High Tech and Critical Metals This presentation will outline the(PDF) Flotation Equipment and Processes ResearchGate

2019年9月29日· A new method, staged flotation for effectively increasing the recovery of ultrafine copper oxide ore with a new type of collector (ZH1, C35 carbon chain xanthate) is proposed for the first time The flotation process and mechanism were examined by flotation tests, entrainment rate analysis, laser particle size experiments and