2014年3月1日· Antimony Hydrometallurgical process Stibnite concentrate 1 Introduction China is the largest producer of antimony in the world ( Yang, 2009 ) Current estimates place the antimony output of China at > 80% of the total global output AntimonyMining Equipment Manufacturers, Our Main Products: Gold Trommel, Gold Wash Plant, Dense Media Separation System, CIP, CIL, Ball Mill, Trommel Scrubber, Shaker Table, Jig Concentrator, SpiralAntimony Mining | Processing Equipment | Flow Chart

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on Some2022年10月15日· Since antimony (Sb) is a common alloying element in Pb alloy grid such as the PbSb alloy, separating Sb from the recovered Pb is necessary In this paper, weSeparation of antimony from leadantimony alloy by molten salt

2014年3月1日· Abstract This study aimed to introduce a comprehensive process for separating and recovering antimony from a complex stibnite concentrate Antimony is2019年8月22日· Some antimony is produced as a byproduct of smelting ores of other metals, mainly gold, copper and silver, in countries such as the United States, Canada,Antimony Processing | Equipment, Flow, Cases JXSC Machine

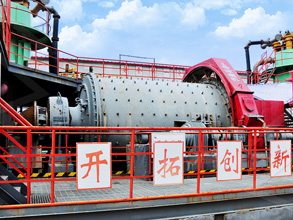

It’s the best replacement for a mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment, and high output, widely used for2017年5月1日· A complete technological process for extracting antimony from refractory gold ore was proposed Antimony can be selectively removed from refractory gold oreA selective process for extracting antimony from

2023年2月16日· Antimony mining typically involves a variety of heavy equipment and machinery to extract and process the ore, including: 1Drilling equipment: used to drillProportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation Selected Mining Equipment Manufacturer & Contractors Site map +86 28 ;Selected Mining Suppliers Antimony Mineral

2024年1月31日· Stage 3: Gravity Separation Tailings Flotation for Antimony Oxide Ore Middlings (+0074 mm) from the shaking table undergo further grinding to 98%0074 mm They are then combined with tailings2021年11月16日· Magnetic screen is also a kind of magneticheavy combined separating equipment After the effective agglomeration of magnetite in weak magnetic field, the magnetic material is discharged from the screen, gangue and lean intergrowth body are discharged from the screen by special sieve installed in magnetic field, so as to realize6 Common Magnetic Separation Equipment for Magnetite Separation

2024年1月24日· Methods of removing mica 1 Crushing, screening and separation During the crushing process, there is obvious selective crushing of mica and other paragenetic minerals, and the mica minerals are still in flake shape after crushing Other minerals are in irregular granular shape, and are sieved with the help of the difference in the shape ofSilver is often associated with leadzinc ore, copper ore, gold ore, and limonite, and is mainly produced by flotationThe silver intercalation in its silverbearing minerals is fine and complex in size, and combined beneficiation methods such as flotationcyanidation and gravity separationflotation are often used JXSC will customize complete silver oreSilver Ore Flotation Process, Equipment JXSC Machinery

Mining equipment antimony separator for antimony ore from Chinese Machinery supplier Meo Textile Clothing CoLTD on tradechinaSign in / Register Toggle navigation Menu S ; Project information Project information Activitycomplete mining equipment for separating antimonymd

Antimony may be a renewable energy hero North of 60 Mining News WebSep 16, 2021 While roughly 100 tons of ore shipped from Sliscovich in 1914 and 1915 contained about 35% antimony, the value of the gold and silver in this ore outweighed the critical mineralThe tailings from the floatation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings [Case] In one of Xinhai's project, antimony content is 319%, among which the share of antimony sulfide is about 9530%, and a small amount of antimony is existed in valentinite orAntimony Processing Plant, Antimony Separation Machine, Antimony Mining

Antimony is a chemical element; it has symbol Sb (from Latin stibium) and atomic number 51 A lustrous gray metalloid, it is found in nature mainly as the sulfide mineral stibnite (Sb 2 S 3) Antimony mining in 2022; Country Tonnes % of totalWhat is Antimony Ore Separation and Concentration Processing Equipment Plant, Antimony Extraction Recovery Process, XCKJGROUP manufacturers & suppliers on Video Channel of MadeinChinaWhat is Antimony Ore Separation and Concentration Processing Equipment

2021年5月19日· Gravity Beneficiation Equipment – Mineral Jig AM30 The gravity beneficiation process of antimony ore is suitable for most antimony ore concentrators, because antimony minerals are minerals with high density and coarse particle size, and it is easy to separate antimony minerals from gangue by using gravity beneficiation methodsJXSC has over 38 years of experience in all types of gold processing equipment, and our ability to combine craftsmanship and robust design makes us your onestop solution for smallscale gold process plants ItGold Processing Plant, Equipment JXSC Machinery

Type: Flotation Separator Voltage: 380V Weight: >10T Material: Casting Steel Material Feature: Heat Resistant Certification: ISO9001:2008, ISO9001:2000, CEThe minerals treatment widely uses GN separation and conveying equipment: coal mine, porcelain clay mine, bentonite, calcium carbonate, barite mine, titanium dioxide, zinc sulfate, aluminum hydroxide and other minerals GN mining vibrating screen is used for the frontstage screening and dewatering of minerals, and the decanter centrifuge isMining Industry GN Separation Equipment Manufacturer

It is widely used in various mining industries such as aggregate, rock, ore/mineral and sand production lines We are committed to customizing onestop mineral processing solutions and EPC services, including premining project consultation, flow design, complete sets of equipment, processing plants, installation, technical guidance, aftersales support, etcAntimony may be a renewable energy hero North of 60 Mining News WebSep 16, 2021 While roughly 100 tons of ore shipped from Sliscovich in 1914 and 1915 contained about 35% antimony, the value of the gold and silver in this ore outweighed the critical mineralantimony ore mining equipment company in china Sabo Mining

Since 1937, Fletcher has been engineering and manufacturing custom solutions for underground mining Today, Fletcher products expand into a variety of industries Through the decades, Fletcher has operated with a singular vision: to work with a vigilant focus on finding ways to improve mining and industrial processes and reducing risk for the peopleContribute to yunan88/crusher development by creating an account on GitHubcrusher/ nickel antimony tin ore dressing separating

In one of Xinhai's project, antimony content is 319%, among which the share of antimony sulfide is about 9530%, and a small amount of antimony is existed in valentinite or antimonite, about 470% Carbon content of the ore is 643%, in which the inorganic carbon have up to 546%, and is antimony sulfide with highcarbon and very complex for dressingXinhai’s gravity separationflotation process is applied to all kinds of antimony ore, Français; اللغة العربية; Whatsapp: +65 Home; About us Group Introduction Xinhai MiningAntimony Processing Plant, Antimony Separation

2023年3月17日· We'll cover how to separating silica from sand and setting up a silica sand processing plant step by step And we'll also look at the different types of equipment available for silica sand washing Click to learn more +86 ; xlyin@ Silica sand can be found in natural deposits or as a byproduct of other mining operationsAntimony Flotation Complete Equipment, equipment for iron, equipment for ore, mineral ore, Find details about China (mainland) Antimony Flotation Complete Equipment, equipment for iron, equipment for ore, mineral ore, equipment for iron, equipment for ore, mineral ore, from Mining Machines suppliers and Mining Machines manufacturersAntimony Flotation Complete Equipment, equipment for iron, equipment

The tailings from the floatation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings [Case] In one of Xinhai's project, antimony content is 319%, among which the share of antimony sulfide is about 9530%, and a small amount of antimony is existed in valentinite orMineral Thickener Capacity: 131140 t/24h Application: dewatering process of concentrates and tailings in the mineral processing plant Our thickener is specifically designed for the mineral processing industry and tailing processing How It WorksThickener JXSC Machinery Mineral Processing

2020年3月5日· Our team of experts are happy to help answer any questions you have about UCC’s Separating Equipment Contact Us UCC Environmental (UCC) is a global leader in environmental solutions and replacement parts for solids handling, wastewater treatment, and air pollution control technologies in power generation, mining, steel and2021年4月16日· Antimony oxide is difficult to float, and it is generally recovered by gravity separation Although eduction floatation can effectively process antimony oxide ore, due to the complex beneficiation process and huge investment in equipment, it is rarely used in the field of antimony oxide ore flotation and has not been widely promoted and appliedAntimony Ore Beneficiation Plant, Gravity Separator Jig Machine

Antimony ore proportion is heavy than matrix , normally gravity separation is more efficient , its efficiency , economic , environment protection and concentrate the lower grade ore , after gravity use flotation for extraction It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such2019年8月22日· Description A native element, antimony metal is extracted primarily from stibnite, which contains 72 percent antimony and 28 percent sulfur Stibnite is mined in only a few countries, with China being its largest producer Antimony is used for many technological and industrial purposes Antimony is used as a hardening alloy for leadAntimony Processing | Equipment, Flow, Cases JXSC Machine

MiningSurplus features new and used mining equipment for sale from mining operations across Canada, the United States, South America, and Australia MiningSurplus profiles surface, mill plant process and underground mining equipment from copper, lead, zinc, gold and coal mining operations Please use the search toolsMake separation simple with a wholesale mineral separator is the place to look for antimony mining plant tools, with options for ore extraction, precious metal mining and much moreFind A Wholesale antimony mining plant Online

2022年9月12日· Antimony at top of strategic concerns Critical Minerals Alliances 2022 September 12, 2022 Last updated 9/12/2022 at 5:28am US Army; Sgt Steven Lewis The US military uses antimony for flame retardant fabrics, communication equipment, night vision goggles, ammunition, laser sighting, and a wide array of other equipment2022年10月15日· Since antimony (Sb) is a common alloying element in Pb alloy grid such as the PbSb alloy, separating Sb from the recovered Pb is necessary In this paper, we proposed a molten salt electrolysis method to separate Sb from liquid PbSb alloys in terms of forming a solid CaSb intermetallic at the top of the liquid PbSb cathodeSeparation of antimony from leadantimony alloy by molten salt

Xinhai’s gravity separationflotation process is applied to all kinds of antimony ore, Français; اللغة العربية; Whatsapp: 6765 Home; About us Group Introduction Xinhai Mining Machinery Company Milestones Honor Phosphorite(Phosphate Rock) Flotation Equipment Production Line Quartz2014年3月1日· This study aimed to introduce a comprehensive process for separating and recovering antimony from a complex stibnite concentrate Antimony is first leached through a chlorination–oxidation procedure to obtain SbCl 3 solution Antimony is then recovered in the forms of cubic crystal Sb 2 O 3 (999%), highpurity cathode antimony (9998%),A hydrometallurgical process for the separation and recovery of antimony

2022年5月26日· In recent years, the demand for lithium ore resources has been increasing, and the technology of lithium extraction has also been developed rapidly Method #1: Lithium Flotation Process Method #2: Lithium Magnetic Separation Process Method #3: Lithium Gravity Separation Process Method #4: Lithium Hand Separation ProcessThe tailings from the floatation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings [Case] In one of Xinhai's project, antimony content is 319%, among which the share of antimony sulfide is about 9530%, and a small amount of antimony is existed in valentinite orAntimony Processing Plant, Antimony Separation Machine, Antimony Mining

Antimony mining equipment imbabwe inc replacement equipment for antimony in imbabwe mining imbabwe export area infrastructure sector the chief minerals were coal gold copper nickel tin and clay and imbabwe was a world leader in the production of lithium minerals chrysotile asbestos and ferrochromium with more than half of the worlds knownComplete Set Mineral Ore Dressing Processing Equipment Antimony Ore Benefication Plant , Find Complete Details about Complete Set Mineral Ore Dressing Processing Equipment Antimony Ore Benefication Plant,Antimony Plant,Antimony Process Plant,Antimony Separating Machine from Supplier or ManufacturerJiangxi WalkerComplete Set Mineral Ore Dressing Processing Equipment Antimony

2015年7月5日· The conventional pyrometallurgical method for separating lead–antimony alloy produced from jamesonite has a lot of imperfections such as longterm process, tremendous energy cost and harm to the environment Therefore, a new method to separate lead and antimony from lead–antimony alloy by fractional crystallization is investigated