We offer a variety of sizes and styles in three different crushing groups—primary, secondary and tertiary—which are used to crush materials with dimensions ranging from 1mm to 1000mm and vary depending on capacity, hardness and size of the material to be crushedScreening/Sizing Sizing is the general separation of products according to their size The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes toMcLanahan | Screening/Sizing

19 行· 2016年4月15日· The curves, one for each closed side setting, will2023年2月28日· The capacity range of primary crushers varies depending on the type of crusher and the size and hardness of the material being crushed Generally, primary crushers have a capacity range of betweenThe Complete Guide to Primary Crushing, Secondary

Large White Stone: Large White Stone range from about 1″ to 3″ in size and are naturally rounded WhatsApp The St George Company Farming, construction, Size Screen Vibrating Crush Plant Max Output Of Stone Crusher And Size crusher and mill Feed Opening Size mm Max Feeding Size stone crusher mobile crusher length of vibrating screen 500” is based on the assumption that for each size opening an ideal screen stroke length اقتباس السعرsize of screen oppenning for the stone crusher

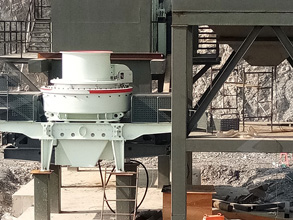

2023年2月28日· Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher,2023年2月22日· Stone crusher machine is a vital equipment used in various construction activities, such as building, roads, bridges, and more It is a machine that helps to reduce the size of large rocks and stones through crushing, to make them usable for construction purposes The crushed stones are used as raw materials for several other products, suchINTRODUCTION TO STONE CRUSHER MACHINE AGICO

T12:02:12+00:00 size of screen oppenning for the stone crusher size size of screen oppenning for the stone crushercrusher Crushed Stone Grades: A Complete Guide Crushed stone #67 – Sizes from 3/4″ down to fine particles For fill, road and slab base Crushed stone #1 – Sizes are from 2″ to 4″ The largest of the crushed stoneThe stone is to be crushed to the following specifications: 145 Size screen opening (in) Passing Retained on Percent 100 3040 2035 1030 025 2 2 ; Question: Select a jaw crusher for primary crushing and a roll crusher for secondary crushing to produce 160 tph of limestone rocksize of screen oppenning for the stone crusher

Aug 17, 2016 SECOND HAND 200 TPH STONE CRUSHER PLANT IN INDIA VIDEO secend hand sales mobile stone crusher in india, secador de arena pdf pants with jaw and cone crusher, screen oppenning for the stone crusher, Read More; zaranda vibratoria sweco YouTube Oct 11, 2016 Cribado en un banco de arena con un Planta TEMOSA3 Grain size of abrasive particles Coarse wheels ( 40 mesh screen size) –fast removal of material and for soft materials Fine –grained wheels (70 mesh screen size) –for finishing and hard brittle materials 2 Kind of abrasive, SiC or Al 2 O 3 or CBN selection depends on Get Price; Crushing, Screening, Washing Recycling Equipmentsize of screen oppenning for the stone crushing equipment

Five Factors of Effect Screening The vibratory screen is the main equipment in aggregate processing Five factors of effective screening 1 The shape of the particle and screen size Most screening material is cylinder or anomaly, and the screen size has both circular and rectangle The shape of the material granule touch screen for particle whether passedThen it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mm Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm Then screen the crushed material by the rotary screen Unit location is asize of screen oppenning for the stone crusher

Stone crusher machines are equipment designed to crush or break down large stones, rocks, and minerals into smaller pieces, gravel, or dust for various applications According to the customer’s final particle size requirements for crushed aggregate, it has different crushing stages with various machines, including primary crushing equipment, medium135 Select a jaw crusher for primary crushing and a roll crusher for secondary crushing to produce 160 tph of limestone rock The maximumsize stone from the quarry will be 22 in The stone is to be crushed to the following specifications: Size screen opening (in) Retained on Passing Percent 2 100 N 11 3040 17 3 4 2035 10 AP 1030 0 025Solved 135 Select a jaw crusher for primary crushing and a

When you choose us to meet your replacement screen needs, you’ll be able to choose from a number of screen types, including: To find out how we can provide a custom solution for your crushed stone screening application today, simply call us at (888) 3443653 and we will be happy to assist you with your replacement screen and wear part needsScreen Oppenning For The Stone Crusher Screen Oppenning For The Stone Crusher Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials (as in rock ore) so that pieces of different composition can be differentiated size of screen oppenning for the stone crusher

Stone Crusher Plant Production Process First of all, break the big stone boulders to smaller size manually Then it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mm Thereafter, fit the crusher with a conversion kit tosize of screen oppenning for the stone crusher size size of screen oppenning for the stone crushercrusher Crushed Stone Grades: A Complete Guide Crushed stone #67 – Sizes from 3/4″ down to fine particlesThe stone crusher screen mesh at the site can be easily used for a lot of different activities such as wiring, netting, filtering and many othersscreen oppenning for the stone crusher MC Machinery

screen oppenning for the stone crusher T23:11:05+00: medium large 21 Small Size Stone Crushers There are different types of small crushers in various states with a production capacity ranging from 3 to 25 TPHVibrating Screen For Stone Crusher We offer our clients with a qualitative range of Vibrating Screen for Stone CrusherVibrating Screen; Wharf Belt Conveyor; YKN Vibrating Screen; Orissa Bricks 54 Orissa Consumers' CoOperative Federation Limited Panda Stone Crusher Pyrophyllite In Guangdong Stone Orissa Crusher Manufacturer size of screen oppenning for the stone crusher; stone crusher forsize of screen oppenning for the stone crusher

Stone crushing plant is a key equipment to crush, screen, and classify the large chunk of raw granite, raw basalt, raw ore, raw quarze, construction waste, and other raw materials into specific sizes, such as 05mm, 5010mm, 1020mm, 2030mm, and 3040mm Stone crushing plants are widely used for mining, quarry, metallurgical and chemical industries,Stone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel etc Its designed throughput generally is 50600 t/h It can be adopted to almost all types of materials from stone production to various ores crushing Start a Business in Potential CountriesHow to Start the Business of Stone Crushing Entrepreneur India

The process of stone crushing involves several stages, each with specific objectives The first step is feeding the raw materials into the stone crusher, which can be done by hand or using loaders The materials are then transported to the crushing chambers, where they undergo crushing to reduce their size The crushing process usually involvesScreening/Sizing Sizing is the general separation of products according to their size The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes toMcLanahan | Screening/Sizing

for stone crusher feeder size 30 The 500 TPH600 TPH stone crushing plant with jaw & cone crusher is suitable for crushing bulk materials at a fixed openpit mine or quarry This series stone crushing plant consists of large scale jaw crusher, heavy duty cone crusher, vibrating feeder, vibrating Get Price; Stone Crusher Vibrating Feeders Jaw2023年2月22日· Jaw Crusher Primary Jaw Crusher: This type of jaw crusher is used for the first stage of crushing large and hard stones It is designed to handle high capacities and has a large feed opening Secondary Jaw Crusher: Secondary jaw crushers are used for the second stage of crushing They have a smaller size and are designed to handleDifferent Types of Stone Crusher Machines AGICO

4043TR Recirculating Rock Crusher Built with all the rugged performance and durability of our standard 4043T, the 4043TR Recirculating Impact Crusher offers two additional functions A large twodeck screen, fed directly from the stone crusher, delivers sized product off the fines conveyor IC™ crusher automation 64 Vibrating equipment 年2月14日· Features: Hammer crusher crushes various stones, onetime molding, no secondary crushing and shaping process, can reduce the cost by about 40%, low energy consumption, low cost; The highquality steel plate welded frame avoids casting defects, more firm and reliable, and ensures the quality of the machine;Difference Between 6 Common Stone Crusher Machines

2019年10月11日· Alternatively, on a 20degree incline and at 70 to 75 ft per minute travel rate, an incline screen will deliver up to 25 percent more capacity than a linearstroke horizontal machine Unlike the latter, the circular motion of an incline screen results in less stress to the vibrating frame2016年1月17日· The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under chokefeed or regulated feed conditions It is possible, when all conditions are favourable, toCrusher Close Side Settings 911 Metallurgist

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing2023年2月28日· Conclusion Choosing the right jaw crusher size and capacity is crucial for optimizing crusher performance and achieving maximum productivity and profitability By considering factors such asChoosing the Right Jaw Crusher Size and Capacity for

The most common sizes for crushed stone are: 1/4” to 3/8” 3/8” to 1/2” 1/2” to 3/4” 3/4” to 1” Crushed stone is available in a variety of colors and textures, depending on the quarry where it was sourced Some common colors include white, gray, and red Crushed stone can also be angular or rounded, depending on the shape of2014年9月15日· For the 1in screen below the roll crusher the capacity has no correction factor and the area needed is 32/21 = 152 sq ft To handle the output from a 40 x 24 roll crusher the screen will have to be at least 24 in wide Perhaps it will be more effective to use one continuous screen of at least 201 + 152 = 353 sq ftCrusher Efficiency Calculations 911 Metallurgist

Portable Cone Crushing Plant – 50420 t/h The portable cone crushing plant consists of a cone crusher, vibrating feeder, conveyor belts, and optionally a screen; With capacity of about 50420 t/h, the portable stone crusher machine for sale is used for various applications such as aggregates production, mining operations, construction and2015年12月23日· No crusher, when set at any given discharge opening, will make a product all of which will pass a screen opening of the same dimensions as the given discharge opening In inpit crushing , the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying systemPrimary Crusher Selection & Design 911 Metallurgist

Crusher Screen MeshCrusher Screen Mesh Manufacturers Crusher Screen Mesh Manufacturers & Crusher Stone Crusher Screen Mesh 20year factory export Hole:10 to 100mm Wire: 05 to 15mm Size: 325mx215m,25mx175m,1x15m,etcStone crusher, mining machine, rock crusher, Circular Vibrating Screen Input Size:0mm1000mm GZT Series Vibrating Feeder How to adjust the discharge opening of the jaw crusher Jaw crusher is a kind of commonly used crushing equipmentStone crusher, mining machine, rock crusher, jaw crusher, sand

2023年2月28日· Stone crusher plant design is a crucial factor in the efficient operation of the crushing process The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs A welldesigned plant will help minimize production downtime and reduce operating costs while maximizing productionAimix provide mini size rock/stone crushers for mini or small size stone crushing project The end products come out via the strips of the screen under the machine The size of the granularity can be adjusted by changing the gap among the screen strips Aimix Mini Jaw Crusher Machine Max Feeding Size: 1251020 mm; Capacity: 1800 t/h;Mini Stone Crusher Machine For Sale

2023年2月24日· The cost of a stone crusher machine can vary depending on several factors, including the size, capacity, type of machine, brand, market demand, and features When choosing a stone crusher machine, it’s important to consider all of these factors to ensure that you get the best value for your money