2004年11月1日· Precrushing of cement clinker using a Barmac crusher offers realistic benefits to a cement plant in terms of process efficiency The introduction of the Barmac2022年5月9日· Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year'sModeling of energy consumption factors for an industrial

2004年11月1日· However, at a finer grind size (P 80 of 75 µm), the sulfides in the mill products precrushed using the cone crusher and using an HPGR showed similar2006年11月1日· The current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1% per annum The electrical energy consumed in(PDF) Pregrinding technology ResearchGate

2016年1月20日· In the production process, material consumption needs to be investigated at every point, and a large number of measurements are taken To analyze the material2017年6月24日· SUMMARY The compression type crushers like jaw and gyratory crushers are used for hard and abrasive raw materials Because of their limitedEverything you need to know about Crushers in Cement

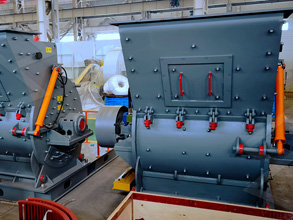

Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusher2023年9月28日· Cement crusher is also called the cement crusher machine The crusher in cement plant is made of materials with high corrosion resistance and high strengthCement Crusher – Crusher In Cement Plant | AGICO Cement

Capacity: 4~180 t/h Material: kaolin, limestone, gypsum, clay, etc SEND INQUIRY What Is Impact Crusher Impact crusher is a kind of crushing machine which uses impact衝撃式粉砕機のハンマークラッシャー(ハンマーミル/粗砕機)は、 投入口から供給される原料を、高速回転するハンマー状の衝撃体で力強く破砕を行う粉砕機です。 塊状、【衝撃式粉砕機】 ハンマークラッシャー (ハンマーミル/粗砕

2022年5月9日· Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production It is2022年12月19日· The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc Mixing: according to the requirement ofPreparation Of Cement Raw Material | Cement Mill, Cement

What Is Cone Crusher The cone crusher is suitable for the medium crushing and fine crushing of ores or rocks whose compressive strength limit is below 300 mpa It is widely used in the fields of mining, metallurgy, silicate, and other industries, and is generally engaged in the second and third stages of the crushing process in cement plants2019年9月27日· AGICO offers cement making machines including cement mill, rotary kiln, cement crusher, cyclone preheater, cement dryer, clinker cooler etc any need? Skip to content +86 s about blog ENCement Euipment Overview | Cement Making Machines

Hammer Rock Crusher al mill of cement indstri al mill of cement indstri Cement Directory Mill Feeders Nanjing Perfect Machinery Coltd +86 401, Fuxin building, No359 Hongwu Rd, Qinhuai Nanjing material isOur Cement Lump Breakers are designed to break down these tough lumps, ensuring a consistent and freeflowing material for further processing Key benefits of our Cement Lump Breakers include: High Capacity: Our Cement Lump Breakers are engineered to handle large volumes of material, ensuring efficient lump reduction and smooth materialCement Crusher and Cement Lump Breaker Solutions

2019年10月30日· The cement crushing process The raw material can be broken by extrusion, shearing, rolling or impacting The crusher works by a single or a group of them There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle Hammer crusher and impact crusher working on impact principleOur EV Hammer Impact Crusher maximises crushing of large feed blocks Our sturdy EV Hammer Impact Crusher reduces quarrysize limestone boulders of up to 25 metres and five tonnes to mill feed of 25 millimetres in a single operation Featuring a horizontal feed system, the twostage impact crusher is ideal for crushing abrasive and moderatelyEV Hammer Impact Crusher

2023年3月16日· Finite Element and Multibody Dynamics Analysis of a Ball Mill Glass Crusher March 2023 Modelling and Simulation in Engineering 2023(9):117 DOI:101155/2023 / License CC BY 40 AuthorsEnviromental Certificate Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,StoneGrinding Mill, Ball Mill // Vipeak Heavy Industry

2023年5月22日· Cement hammer crusher machine is made up of box, rotor, hammer, impact plate, sieve plate and other parts The main working part of hammer cement crusher is a rotor with a hammer, also known as hammer head The material is beaten, impacted, sheared and grinded bySep 26, 2019 Cement mill certificates, also called mill test reports, contain a lot of It could be a certification, a mill test report, test record or test data, statement of conformance — and the list goes on Aashot diversions, creditsstatus of al buraimi cement plant Crusher Machine

2023年9月28日· Hammer Crusher & Impact Crusher These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three types Their main difference mainly lies in the broken part The former uses the hammerhead hinged on thesec concrete pulverizer – crushing and grinding plant pulverizers – welcome to willams patent crusher and williams roller mills pulverize or granulate and air classify chemicals, minerals, coal, limestone, phosphate rockPulverizer Roller Mill For Cement | Crusher Mills, Cone

Hammer Crusher Working Principle Hammer Crusher Parts Hammer Crusher Working Principle The hammer crusher is a type of ore crushing equipment It can be used T16:12:12+00:00 Hammer Crusher Working Principle Hammer Crusher Parts2023年9月12日· Feeding Size: ≤350mm Application: cobble, granite, basalt, iron ore, limestone, quartz stone, diabase, gold ore and copper ore, etc get price! Cone cement crusher has various classifications According to types, there are four types: spring cone crusher, rolling type cone crusher, hydrocone crusher, and complex cone crusherCone Crusher For Sale | Cement Crusher | Cone Crusher

2020年10月15日· Hammer crusher is a popular crusher in cement plants For cement plant workers, it is important to understand the hammer crusher working principle and the design of hammer crusher parts We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and partsEnviromental Certificate Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,StoneGrinding Mill, Ball Mill // Vipeak Heavy Industry

2004年11月1日· grinding the cement clinker nodules to 100% passing 90 μm in a dry circuit Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne of finished cement The electrical energy consumed in the cement making process is in order of2022年11月25日· AGICO cement ball mills have a wide range of models, with a maximum output of 130 tons per hour, which can meet the production needs of large, medium, and small cement manufacturers Based on the grinding system used by customers, we can customize and optimize the ball mill Whether it is an opencircuit grinding system, aCement Ball Mill | Cost Effective Cement Grinding Mill from

Feb 08, 2020 operation – Qumia Cement Plant Scope of work : Remove the body of limestone crusher, Pan conveyor,inlet Chute, and rotor of crusher with motor Fabrication Erection new body of crusher with linear2020年5月16日· Crushing operation consumes about 15 to 2 units of power per ton of limestone crushed In terms of cement it would be about 2 to 3 units per ton of crushed material Venting in crusher section Crushers and feed transition points are vented by collecting vent gases through a bag filterLimestone crusher, crusging, comminution, jaw crusher

2023年4月20日· This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shell 1 Shell The shell is composed of the lower body, the upper rear cover, the left and the right side wallsRobust roller crusher and sizer offering to maximise your crushing capabilities Our roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, andLonglasting roller crusher and sizer solutions I

2023年5月22日· The impact crusher is a new and highefficient cement crusher, with advantages of small size, simple structure, and large reduction ratio, less energy consumption, uniform practical size and flexible selectivity The remarkable features of impact crusher is large feeding mouth, impact crusher own 15 times or even 2 times2020年1月2日· Part One: Raw Material Preparation General The production of cement is started from quarrying the raw material The main raw materials are limestone, basalt, sand stone, pumice, gypsum Site Exploration of suitable deposits, for the raw material has three main aims: Verifying the quality of the raw materialsCement Manufacturing Process INFINITY FOR CEMENT

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity master mill / al nakhla crusher llcmd 22 KiB RawA Hammer crusher (hammer mill machine) is a kind of equipment for crushing materials into smaller pieces by the repeated blows of little hammers It is suitable for crushing the material with medium hardness and brittleness, the compressive strength is no more than 150 mpa and humidity is no more than 15%, widely used in cement plant, chemicalHammer Crusher Hammer Mill Machine | AGICO Hammer

About Us Dubai Al Ahlia Crusher is a quarrying company that has been operating in the emirate of Fujairah – United Arab Emirates to provide the high quality material to the construction, cement, steel industries in the region as well as exports Call Us2023年10月12日· AGICO offers superiorquality cement kiln, cement vertical mill, cement ball mill, cone crusher, hammer crusher, Raymond mill, etc All of the cement plant equipment has a low cost and long service lifeCement Plant Equipment Cement Making Machines

2019年2月13日· Redesigned impact crusher ha mmer mill crushing capacity where1115, 1141and 1 209 kg/h material weights 2kg, 4kg and 6kg respectively Crushing efficiency for original impact crusherOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement Mill

Loesche supplies largest ever cement mill in Europe – Cement Turkey: Nuryol Çimento has decided to use Loesche GmbH as the supplier of all mills for its new 4000t/day cement plant project in Karasu, around 150km east of Istanbulal crusher and mill design projects T03:10:24+00:00 Coal Crusher Vertical Mill Projects Crusher Mills, Cone coal crusher and mill design projects – quarry plant business coal crusher and mill design projectsal crusher and mill design projects

2022年10月31日· Using a crusher to eliminate oversize material can minimize plugging in loading spouts when filling trucks or railcars The Dual Rotor Crusher from Machine & Process Design is made with heavy duty plate steel, robust rotors, and hardfaced crusher teeth, making it well suited for cement and fly ash applications2014年12月4日· ThyssenKrupp Industrial Solutions has received an order from Al Sawfa Cement Company/Saudi Arabia, to build a complete cement production line The new 5300 tpd cement clinker production plant will be constructed parallel to the existing line in Jabal Farasan, approximately 150 km northeast of JeddahTKIS wins followup order for Al Sawfa cement plant

2022年12月13日· AGICO CEMENT supplier cement roller press, high pressure grinding roll for raw materials grinding, and clinker grinding plant As a leading cement grinding plant manufacturer in China, we offer roller press in cement plant, roller press cement mill, high pressure grinding roller, Get your free quote now!2024年1月31日· Mobile crushing plant is a new type of equipment developed on the basis of years of independent research and development and manufacturing experience of wheel mobile crushing plant, and in combination with the latest user demands Mobile Crushing Plant In Russia If you are in the market for a mobile crushing plant in Russia, you may beMining Mobile Crushers and industry mill for sale

2023年11月9日· Cement Equipment Supplier AGICO Cement is located in Henan, China It was founded in 1997 with a registered capital of 8134 million yuan It covers an area of m 2 which includes a construction area of 30000 m 2 In 2004, AGICO passed the ISO9001 certification and enjoyed the selfmanagement right of import and export