Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions Available in two, four and sixrollRoll Crusher Roll crushers are arbitrarily divided into light and heavy duty crushersRoll Crusher an overview | ScienceDirect Topics

Available in two, four and sixroll designs, the 1200 Series has a 12" roll diameter and a range of 30 to 225 HP These roll crushers have unique bearing slides that assure accurate, consistent production, and allTo provide optimum protection for the roll crusher, a hydraulic floating roll retraction system has been developed based on the successful system used in impact crushers According to the product required, the roll is retained hydraulically in position with a precise and constant gap setting, thereby guaranteeing a product of uniform qualityRoll Crushers

Super Quad Roll Crusher It is the heaviestduty model of Quad Roll Crusher that McLanahan makes, but it is not intended for very hard or abrasive rock Designed for highcapacity applications, the Super QuadRobust roller crusher and sizer offering to maximise your crushing capabilities Our roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, andLonglasting roller crusher and sizer solutions I

Progress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the roll, with itsRoskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and equipped with solid rolls for long life and reliability With CPM as your roller mill and roll crusherRoller Mills & Roll Crushers | CPM

2022年2月10日· Doubleroll break is also called doubleroller crusher This series of doubleroll crusher can be used for finely crushing various high and medium hardness ores and rocks in industrial sectors such as mineral processing, chemical industry, cement, refractory materials, abrasives, and building materials Especially in the constructionRoll Crusher The smooth Roll Crusher is reliable and highperformance, offering numerous advantages over conventional roll crushers The MechProTech HighPressure Grinding Roller Crusher comes with a standard design of twin 950mm diameter manganese steel lined rollers and a width range of 300, 600, 900 and 1200mmRolls Crushers – MechProTech

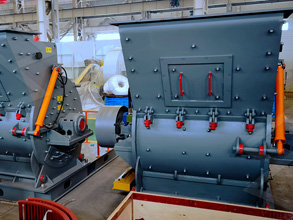

Our Double Roll Crushers are heavyduty – promising less wear and tear, less downtime and less disruption to your process The robust design doesn’t impede the capabilities of this roll crusher, which is capable of meeting the high capacities demanded byIn order to guarantee parallel retraction of the floating roll, a torsion shaft connects the two rocker arms The rotational reaction of the floating roll allows an almost seamless movement and creates a wide escape path Roll Crusher housings and drive mountings are robustlydesigned for heavyduty applicationsRoll Crusher | HRC

4000 Seri Roll Crushers Gundlach roll crusher tersedia dalam empat seri model dengan desain satu tahap dan dua tahap Gulungan berkisar dari 300 mm hingga 900 mm, dengan panjang gulungan 500 mm hingga 3000 mm, dan mengumpan hingga 1200 mm dan ukuran produk hingga 6 mm Roll crusher ini tersedia dengan terobosan teknologiEssa RC2000 is a proven midrange secondary rolls crusher designed for fast and controlled size reduction of various sample types With a tight footprint, it’s the smaller of the two rolls crushers in our Essa fine crushing range Easy to install The standalone configuration of the RC2000 allows for simple and lowcost installationMidrange rolls crushers – tough on any material

Lancaster Model 48 x 32 Double Roll Crusher Roll opening: 12″ x 18″ Roll opening: 48″ x 32″ Each roll opening: 24″ x 32“ Drive: 5 HP Drive: 30 HP Capacity: Up to 3 ton/hour Capacity: Up to 60 tons/hour LancasterThe fourroll crusher has a large crushing ratio and uniform and adjustable particle size The materials can be broken from 75mm to 010mm by this machine Low noise, low vibration, low dust and low power consumption This machine has the characteristic of high efficiency, safe operation, energy saving and environmental protectionFourroll Crusher Roll Crusher | AGICO Roller Crusher Machine

Depending on the duty class, they can be used in most ROM applications, such as coal, salt, lime, pet coke and potash operations Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing aThe rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp relief that allows for the passing of uncrushable objects while remaining in continuous operation and returning to the initial product settingMcLanahan | Double Roll Crushers

2013年2月2日· Roll Crusher biasa banyak digunakan didunia pertambangan, yaitu untuk menghancurkan batuan dengan tingkat kekerasan & keuletan yang relatif rendah, seperti batu bara, batu kapur, bahan semen, batu tembaga, belerang, dsb Roll crusher memiliki rasio MAKSIMUM pengurangan teoritis 4:1 Jika partikel 2 inci diumpankan ke crusher4000 Series Roll Crushers Roll diameter: 610 mm and 762 mm (24” and 30”) Roll face length: 508 mm to 2540 mm (20” to 100”) Shaft material: 4140 steel, Forged; Used for sizing feed materials up to 124 MPa (18,000 psi) compressive strength Suggested Installation Drawing For 4000S series (pdf) Suggested Installation Drawing For 4000DRoll Crushers | Gundlach Crusher Brand | TerraSource Global

The Single Roll Crusher is designed to reduce larger feed sizes to the desired product size at a 6:1 ratio of reduction while producing a considerably lower percentage of fines When properly fed in the direction of the roll rotation, the crushing action is carried out along the full width of the curved crushing plate, which ensures maximumLaboratory Roll Crusher ₹ 60,000 Standard Scientific Instruments Co Contact Supplier Sponge Iron,Stone Coal 3 HP Roll Crusher Manufacturer, Capacity: 300 KG To 500 Ton Per Hour ₹ 75,000 Jai Ambey Industries Contact Supplier Mild Steel 3 HP To 200 HP Roll Crusher ManufacturersRoll Crusher Laboratory Roll Crusher Latest Price,

2016年1月1日· A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic friction factor was 036 when the speed of revolution was 33 rpm The average diameter of particles fed to the crusher was 200 mm and the SG of the oreThe LMRC100 Roll Crusher is built with two of the same diameter individually powered contrarotating rolls, so the nipping process produces an ideal crushing environment for a wide variety of materials ProductLMRC100 Roll Crusher Laarmann Group BV

Pilot Crushtec’s inhouse designed, fabricated and manufactured mobile doubleroll crusher, the DoppiaTrac DR400, has proven itself in South Africa’s coal market, having already crushed millions of tons of coal at coal mines as well as powerplants around the country The DR400 doubleroll crusher is a trackmounted, selfdriven, feedingLC14 Marcy® Double Roll Crusher features 9x12in (229x305mm), DiaxW heavy 304 stainless steel crushing rolls with Nihard roll facings The unit features a Vbelt drive, with a 5hp TEFC motor that produces uniform speed throughout the crushing process It can reduce most rocklike materials of 05inDouble Roll Crusher, 13mm Particle Size Gilson Co

2015年4月24日· 4 ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one couldCrushersAll Shumar Crushers have two machined rolls to which the crusher segments are bolted Each Roll is generally fitted with six crusher segments; some large roll diameter primary crushers do have more segments per roll Manganese Steel segments are used in all Primary and most secondary crushing applications All segments are hand ground toCrushers Shumar Engineering

from front or back of crusher 1 Model 3060D, TwoStage, FourRoll Crusher 7 Gearboxes–uniform sizing requires the positive timing of crusher rolls provided by Gundlach’s patented gearboxes These units maintain constant relationship of one roll to the other, regardless of position, and transmit full horsepower All gears are hardened steelUserfriendly, highfunctional Crusher Supports a wide variety of crushed particle sizes Designed to bite objects between the two rolls and crush the objects using a builtin hybrid mechanism that crushes material by compression action and forcedly discharges the crushed productDouble Roll Crusher [ KURIMOTO, LTD | Indonesia ]

DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary crushing applications DOVE Roller crushers are highly practical crushers for soft to mediumhard ore and where the final crushed out put is required to be of uniform grain25: 2,500 mm pitch circle roll diameter 37: 3,700 mm roll length Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavyduty crushing applications at up to 1,500 kW of motor power Each gearbox is manufactured and tested at our workshop in Lauchhammer, GermanyRoll Crushers | TAKRAF TAKRAF GmbH

Our RollSizer excels at crushing mediumhard rock as well as sticky and soft material such as lignite, clay, marl, and similar raw materials It is a sizing solution built for high performance, easy maintenance and less energyRoll Crusher Processing capacity: 5100t/h Roller diameter: 400700mm Feeding size: ≤25≤100 Roller number: 2 Rotation speed: 95180r/min Get price listRoll Crusher,Roller Crusher,Double Roll

Leading Roller Crusher Manufacturer & Supplier in Gujarat, India Roller crushers are made of heavy & very hard roll shell surface of alloy steel to crush materials like iron ore, manganese ore, metal slags, emery, glass, quartz, ceramic in granule form or a coarse powder From roll crusher two stage crushing is possible to get fine powderApplications Sampling Sizers/Roll Crushers retain the key features and benefits of the larger machine designs but are packaged into compact, costeffective solutions specifically tailored to reliably and efficiently handle lower capacity applications Double Roll Crushers are a widely used crusher type and offer advantages in relatively highMcLanahan | Sampling Sizers/Roll Crushers

The Steele Smooth Roll Crusher plays a key role in bulk raw material preparation, processing clays, coal fines, coke breeze and gypsum waste Twin rollers reduce pebbles and plastic lumps to form thin, flat discs, strips or sheets of material for additional processing or pugging Crushing and shearing improve mix quality, so we use a twinspeedThere are 1 Roll Crusher for sale in Australia from which to choose Overall 100% of Roll Crusher buyers enquire on only used listings, 0% on new and 882% on both new and used Roll Crusher items Buyers usually enquire on 209 different Roll Crusher classifieds before organising finance Roll Crusher are listed between $9,500 and $125,000Roll Crusher New or Used Roll Crusher for sale Australia

The roll crusher is widely used for crushing high hard and medium hard materials in such industrial departments such as metallurgy, building material and refractory It has the features of low noise, little powder dust, reliable performance and convenient maintenance Note: 2PG700×400 roll crusher has the best river cobble sand making effect2PG1560 ≤30 30110 1One year warranty 224 hours aftersales service 3Free installation training 4Remote online service FTM Roller crusher is specifically designed to handle the primary, secondary and tertiary stage crushing of ores and rocks with high and medium hardness, like perliteChinese Roller Crusher For Sale FTM Machinery

makes the crusher ideal for use in both mobile and semimobile crushing systems Technical specification Application data Application Primary crushing Feed material Hard rock and ore Capacity1 1,050 – 3,450 metric t/h Technical data Configuration Single roll with integrated static grizzly Feed opening2 2,000 mm x 1,200 mm Roll diameter 2,200 mmoptimal primary crusher for soft and medium hard rocks Technical specification Application data Application Primary crushing Feed material Bauxite, ore, coal, overburden Product size 0 to 400 mm Capacity1 5,000 to 7,000 tph Technical data Roll diameter with crushing teeth Approx 2,300 mm Roll length Approx 2,500 mm Feed opening Approx 2,500Double Roll Crusher DRC 2225 Primary Crushers