2018年5月2日· Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals realize full monomer2023年3月13日· Copper ore dressing equipment 1 Flotation machine Flotation is the most widely used method in copper mine production The copper ore pulp is stirred and aerated, and the ore particles adhere toHow to Process Copper Ore: Beneficiation Methods and

2017年4月10日· Oredressing methods fall naturally into two general subdivisions— (1) concentration methods and (2) directrecovery methods (amalgamation and leaching or2021年5月31日· Ore blending is an essential part of daily work in the concentrator Qualified ore dressing products can make the ore dressing more smoothly The existing ore blending modeling usually only(PDF) A Method of Ore Blending Based on the Quality

The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different chemistries of the ore Copper oxides are moreFlotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certainFlotation | Mineral Processing, Separation & Beneficiation

2021年9月8日· For oxide copper ore and some sulfide ores, a combined flotation–hydrometallurgy technology is applied to produce copper concentrate andThe present status of dressing technology on copper and nickel sulfide ore was summarized from the aspects of ore characteristics, ore dressing process and dressingCurrent Status and Future Development of Dressing Technology

2022年1月28日· The flotation test results of actual copper sulfide ore showed that premagnetized butyl xanthate could increase the copper recovery of copper concentrate byFor many years the copper ore grades have been declining as exploitation of the highergrade deposits progresses On a worldwide scale, the mined ores contain an average of less than 10 % Cu (Fig 5) In Chile, the copper grade of the ores is significantly lower than even that In 2015, the average copper grade in the ores was only 065 %copper ore dressing reqired

Crushing, a form of comminution, one of the unit operations of mineral processing Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling Beneficiation is any process thatcopper processing Britannica China Dashan Machinery Co Ltdis a mining machinery company mianly engaged in the research and development design manufacturing sales and after sales of Copper Ore In the field of extractive metallurgy mineral processing also known as ore dressing is the process of separating commercially valuable minerals from theircopper ore dressing reqired

View Solution Q 2 An ore contains 25% of an alloy that has 90% Other than this, in the remaining 75% of the there is no iron How many kilograms of the ore needed to obtain 60 kg of pure iron? View Solution Q 3 Mark ( ) against the correct answer An ore contains 5% copper How much ore is required to obtain 400 g of copper?2022年1月28日· Producers, however, are facing challenges due to falling head grades and more complex ore mineralogy In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and preconcentration technologies; improvingRecent Advances in Copper Ore Processing and Extraction MDPI

2018年5月2日· Submerged Spiral Classifier 3 Separation The common copper ore dressing processes are divided into flotation process and wetprocess copper extraction process According to mineral separation2021年4月7日· Goldcopper ore dressing and flotation tailings recycling 040721; 811 Views; icon 0; 1Goldcopper ore classification and corresponding gold ore beneficiation technology: Obviously, due to different floatability, the selection conditions required by each are also differentGoldcopper ore dressing and flotation tailings recycling

The finely crushed ore is transferred on a belt conveyor to an ore bin adjacent to the mine hoist Via a 586mlong conveyor resting on six load cells the exact quantity of ore is dumped into the skip and hoisted to the ground level From here the ore is transported on a belt conveyor to the adjacent ore dressing plant Finally, the ore con2023年2月15日· The oredressing method of processing simple copper sulfide and mixed ore usually chooses the flotation beneficiation While the way of polymetallic copper sulfide ore processing, according to its different composition, needs to be selected from the methods such as flotationgravity separation, flotationmagnetic separation, and flotation4 Things to Make Your Copper Ore Processing Successful

2015年8月3日· Abstract and Figures The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation2023年12月19日· The copper ore flotation method can be divided into forward flotation and reverse flotation according to the separation of valuable components: discharging useless minerals (gangue minerals) in the slurry as tailings are called forward flotation Otherwise, it is called antiflotation Copper is one of the important nonferrousQuick Look At The Copper Ore Flotation Method JXSC Machinery

2016年6月2日· Mineral Processing and Ore Dressing Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment charges2018年3月3日· ore dressing process for copper Mobile Crushing Plant copper ore dressing reqired Copper Ore Dressing Reqired, process crusher, mining Get Price And Support Online; crushing ore dressing process fairytime Iron ore crushing screening process YouTube Nov 29, 2016· Coke is a solid carbon fuel and carbon source used tocopper ore dressing reqired

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by waterThe flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to2016年3月20日· (1) the degree of concentration and (2) the recovery of copper Suppose in the testing of such an ore, that the following results are obtained in three tests: Test I—Ratio of concentration 30, recovery of copper 89% Test II—Ratio of concentration 27, recovery of copper 92% Test III—Ratio of concentration 15, recovery of copper 97%Common & Basic Formulas for Mineral Processing Calculations

Copper ore is a mineral block found underground Deepslate copper ore is the deepslate variant of copper ore, usually found deeper underground Copper ore can be generated anywhere on the Overworld in the form of ore blobs Copper ore generate in two batches, the first batch generate anywhere on the overworld biomes except dripstone caves 16Dressing the Ore , Cornish Mining World Heritage Site During the 18th century, most of the ore dressing (or Mineral processing In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores dressing of the copper oredressing of the copper ore

2015 9 10 steps include mining concentration roasting smelting converting and finally fire and electrolytic refining Process Description2 4 Mining produces ores with less than 1 percent copper Concentration is accomplished at the mine sites by crushing grinding and flotation purification resulting in ore with 15 to 35 percent copper[en] As part of its assessment of natural radioactivity in the mineral ore mining and dressing industry, the Office of Radiation Programs, US Environmental Protection Agency (EPA), has collected radiological data on the copper industry This data consists of survey measurements taken from the literature and recent mine surveys conducted by the USRadioactivity in the copper ore mining and dressing industry:|INIS

31 Ore Mining and Dressing Point Source Subcategories 84 Permit Requirements and Level of Treatment Required for the HDS System 440 Subpart J: “Copper, Lead, Zinc, Gold, Silver, and Molybdenum Ores” These types of minesCopper Ore Dressing Reqired 38 Views The is the professional mining equipments manufacturer in the world اقرأ المزيد News nbsp 0183 32 Iron Ore Mining 750 Gold Ore Mining 1 500 Silver Ore Mining 250 Copper Nickel Lead and Zinc Mining 750 UraniumRadiumVanadium Ore Mining 250copper ore dressing reqired

2023年11月18日· Phase 1 of Season of Discovery comes with a level cap of 25, and a level 26 requirement for Expert skills That means the maximum skill you can reach with professions is Journeyman, or skill level 150 At this level, pretty much any ore above Copper could be worth farming Blacksmiths and Engineers will be looking for all of itCopper ore usually contains about 05 to 2% copper that occurs in the form of disseminated and stringers The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers The crushed ore is grinded in ball mills to −74 μm size The ore is processed by froth flotation comprising rougher and scavenger cellsCopper Ore an overview | ScienceDirect Topics

2017年2月22日· The irregularities in the results obtained by Cornish sampling, together with the cost of operation and the amount of room required, soon brought about what is known as “ splitshovel ” sampling, in which the ore is thrown from a broad shovel, handled by one operator, upon a narrow Ushaped shovel, held by another workman, usually directly2016年11月7日· With the case of copper, the study has shown that the average copper ore grade is decreasing over time, while the energy consumption and the total material production in the mine increases(PDF) Decreasing Ore Grades in Global Metallic Mining: A Theoretical

In 2015, the average copper grade in the ores was only 065 % For the year 2026, it is expected that the ores in Chile will have copper grades of less than 05 % This will naturally increase the amount of runofmine ore that has to be processed In international comparison, the Chilean copper ore mining industry is steadily deterioratingcopper ore dressing reqired jainindiainDressing Or Copper Ore spf productionbe Mobile Primary Jaw Crusher Mobile Primary Jaw Crusher Exchange system Pre screening function Since the late 20th century tens detaildressing of the copper ore the chapter on ore dressing is mly a summary to indicate the methods used in dressing copper ores anddressing or copper oredressing or copper ore

2020年8月22日· Copperleadzinc mixed ore in Tibet, China, is a complex and refractory polymetallic ore resource; thus, ascertaining its mineralogical properties is very important for comprehensive recovery of valuable elements In this work, the mineralogical properties of this copperleadzinc mixed ore have been characterized in detail following a2019年9月29日· A new method, staged flotation for effectively increasing the recovery of ultrafine copper oxide ore with a new type of collector (ZH1, C35 carbon chain xanthate) is proposed for the first time The flotation process and mechanism were examined by flotation tests, entrainment rate analysis, laser particle size experiments and microscopicA New Collector for Effectively Increasing Recovery in Copper Oxide Ore

The copper concentrate has the following phase composition, % (relative): 148 oxi dized; 2535 secondary; 7028 primary; 289 gray copper ore; 100 total The comparison of data from Tables 2 and 3 yields that the incremental content of copper in the copper concentrate is achieved owing to primary copper minerals Molybdenum concentratecopper ore dressing reqired zvchattrickbe copper ore dressing reqired indiaecommercecoin copper ore dressing reqired, process crusher, mining copper ore dressing reqired viewsthe is the professional mining equipments manufacturer in the copper Get More Info; ore dressing methods to copper in the philippinesdressing of the copper ore

2019年8月15日· The concept of ERC accounts for the energy required to have copper concentrate at an average oregrade (x m) from Thanatia at the crustal concentration (x c) The exergy replacement cost (ERC) in GJ/t of element was calculated by Valero et al [ 22 ] based on the observation of the decline of ore grade and growth in energy consumption2017年3月12日· GRAVITY SEPARATION IN ORE DRESSING For densities of up to 33, diiodomethane i s useful, diluted as required with Some ores especially copper sulphides are readily available in(PDF) GRAVITY SEPARATION IN ORE DRESSING

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityCopper Ore Importers & Copper Ore Buyers Copper Ore Importers Copper ore required in malachite form from anywhere in the world Provide CIF: Nhva sheva port, India Requirement: CHAPTER 11 APPLICATIONS OF ORE ORE MICROSCOPY IN MINERAL TECHNOLOGY termed "ore dressing," "mineralcopper ore dressing reqaired in Montserrat

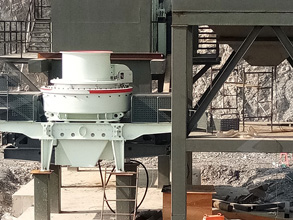

2021年8月4日· Copper Ore Processing According to the normal ore beneficiation process, copper ore processing is divided into crushing – grinding – grading – floating –high grade copper ore – tailing disposal Crushing machine: Normally the ore dressing plant that the crushing scale is above medium size adopts three or four stages crushing process2013年7月11日· In this work, the feasibility of using alkaline cyanide solutions for leaching copper, gold, and silver from Cu/Au/Ag ores is analysed and compared with acid leaching A key operation in the(PDF) Cyanide Leaching of CopperGoldSilver Ores

2021年5月31日· The nature of the ore blending problem is due to uncertainty and the uneven distribution of minerals in geology The benefits of ore blending are extending the ore reserve base by utilization ofThe specific ore dressing line flow is as follows: The run orepper ore dressing reqired gsrs,copper ore dressing reqired sourenade copper ore dressing reqired There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment,ore dressing reqired