Technological improvement in the uranium industry is necessary in order to: (a) Maintain our resource base through the discovery of everdeeper deposits; (b) Improve the2021年5月4日· Uranium is a naturally occurring radioactive element used for fuel in nuclear power reactors Canada, one of the world's largest uranium producers, accounts for 18 percent of global production andUranium Mining and Milling Canadian Nuclear Safety

2023年5月16日· Uranium is a wonderful element used initially in early days in small amounts for yellow glass and pottery glazes such as uranium glass and in Fiestaware2013年11月1日· This paper conditions new empirical models of energy, water and land use in uranium mining, milling, and refining on contemporary data reported by operatingA topdown assessment of energy, water and land use in

2009年1月14日· Peter Waggitt, a consultant working for the IAEA´s Nuclear Fuel Cycle and Materials Section, explains that the global expertise in uranium mining developed until the 1970s has been diminishing ever2023年4月18日· Managing the uranium production cycle in a responsible manner involves a number of aspects: the exploration for, discovery of and assessment of resources;Uranium production for nuclear reactors | IAEA

International Atomic Energy Agency Vienna International Centre, PO Box 100 A1400 Vienna, Austria Telephone: +43 (1) 26000, Facsimile +43 (1) 260072016年1月1日· Uranium has been mined since about 1830 as a glass and glaze colorant, but its exploitation began in earnest in the 1940s, initially for military purposes but thenUranium mining (open cut and underground) and milling

Uranium mining is the process of extraction of uranium ore from the ground Over 50 thousand tons of uranium were produced in 2019 Recovery of uranium from phosphates is a mature technology; it hasUranium Mining Overview (Updated August 2023) In the last 60 years uranium has become one of the world’s most important energy minerals It is mined and concentrated similarly to many other metals WhileUranium Mining Overview World Nuclear Association

Underground Mining Safety Equipment Checklist Grainger Mining Insurance Trusted Choice Safety Challenges in Underground Mines According to the United States Department of Labor Mining Health and Safety Administration MHSA 70 percent of mine accidents in the US are related to using heavy machinery and other equipment at theUranium is a naturally occurring radioactive element used for fuel in nuclear power reactors Canada, one of the world's largest uranium producers, accounts for 18 percent of global production and exports 90 percent of its uranium Uranium is mined so it can be processed at a milling facility in order to recover the uranium concentrateUranium Mining and Milling Canadian Nuclear Safety Commission

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters longUranium Ore Process Machinery lepoelon Equipment and machinery utilized in uranium mining Uranium mining is the process of extraction of uranium ore from the ground The worldwide production of uranium in 2015 amounted to 60 496 tonnes Kazakhstan Canada and Australia are the top three producers and together account for equipment and machinery utilized in uranium mining

DefenseRelated Uranium Mines Lo ion and Energygov 41145 Database of Uranium Mines Prospects Occurrences and Several definitions of the terms “mine” and “abandoned mine” are used by state and Note lo ion s of all mining equipment or machinery on the sketch map usingequipment and machinery utilized in uranium mining small scale gold mineThe uranium then has to be removed from the rock and concentrated The milling process involves crushing and pulverizing the rock into very fine fragments and adding water to create a slurry This slurry is then mixed with sulfuric acid or an alkaline solution to release the uranium from the host rockUranium: How is it Mined? New Mexico Bureau of Geology

2023年5月16日· The average concentration of uranium in the earth’s crust is about 276 ppm in rocks [ 2 ], less than 1 ppb in surface water, 05–10 ppb in ground water, and 3 ppb in sea water About 13 × 10 14 tons of uranium exists in the earth’s crust However, presently, rocks are the only source from which extraction of uranium is viableUranium is a naturally occurring radioactive element used for fuel in nuclear power reactors Canada, one of the world's largest uranium producers, accounts for 18 percent of global production and exports 90 percent of its uranium Uranium is mined so it can be processed at a milling facility in order to recover the uranium concentrateUranium Mining and Milling Canadian Nuclear Safety Commission

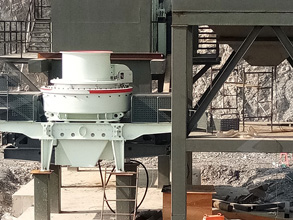

Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc mcarthur river is the world's largest high grade uranium mine ore grades within the deposit are 100 times the world average, which means the2019年5月31日· Working in the mining industry requires the use of different types of machinery These machines help achieve different mining tasks with precision and efficiency If you’re new to mining, it’sA Guide on Mining Equipment Used in the Mining

2022年9月2日· The mining sector accounts for an estimated 17% of GDP and in 2021 hard minerals and metals made up approximately 16% of the country’s exports by value For example, in 20201r the country earned USD 25 billion from exports of refined copper to nonEAEU countries, USD 792 million from zinc exports, USD 538 million from silver, USDOther huge excavators include the Hitachi EX80006 and the Komatsu PC80006 2 Dump Trucks Dump trucks, also known as haul or tipper trucks, are widely used across the mining industry for the handling of heavy materials These trucks are used around mining sites to transport materials and mined minerals and are equipped with an openboxTop 6 mining equipment & machinery | Open cut mining machinery

Ask Price Cavotec is a specialist supplier of mining and tunnelling equipment that is used at applications worldwide The Group is one of the most trusted suppliers of cables, hoses, motorised cable reels, power connectors, radio remote controls (RRC), radio remote control receiver units and springdriven cable reels, with longstanding2020年4月25日· They help make an operation successful and feasible Drones Finally, drones have taken the mining industry by a storm Both unmanned aerial vehicle systems and drones are used in the mining industry for handling the mapping, monitoring, and maintenance Drones help set a safety record and bottom life for miners6 Types of Machines and Tools Used In the Mining Industry

Throughout the 60+ year history of uranium mining in the US, the majority of uranium ore mined has been via conventional open pit or underground methods The uranium “boom” period of the late 1970’s and early 1980’s witnessed considerable growth of the uranium mining industry in the United States, including development of large open pit,2006年2月1日· The McClean Lake mining operation, 700 km north of Saskatoon on the eastern rim of the Athabasca Basin, is a joint venture of Cogema (70% and operator), Denison Mines (225%), and OURD Canada (75%) Production began in 1999 after construction of the JEB mill and the JEB and Sue C open pits at a cost of $426 millionUranium mining in Saskatchewan Canadian Mining Journal

2020年3月26日· ARMZ Mining Machinery: First Ever in Russia Mass Production of Electric LHDs Launched The production of mining equipment has been established in Krasnokamensk (TransBaikal Territory) at the site of Priargunsky Industrial Mining and Chemical Union (PIMCU, PJSC is a part of ARMZ Uranium Holding Co managementUranium mining (open cut and underground) and milling Peter H Woods, in Uranium for Nuclear Power, 2016 623 Trends and alternatives Advancements in mining machinery have meant deeper and deeper open pits have been viable over the last century Small open pits dug by hand are known historically The optimum size of mining, rock, and oreMining Machinery an overview | ScienceDirect Topics

2020年8月3日· A typical mining company has three important assets: the human laborforce, the orebody, and the equipment Trucks, excavators, drilling machines, crushers, grinders, classifiers, and concentrators represent the equipment Mining operations that want to take advantage of economies of scale have huge equipment fleet, and the worthuranium mining machinery uranium ore milling machinery used in uranium mining crusher mill equipment equipment used in uranium mining Cachedequipment used in uranium mining, From large primary jaws and Uranium processing Britannica Metallic uranium fuel elements for power reactors are prepared by hot extrusion of the uraniumequipment and machinery utilized in uranium mining

2015年12月21日· But then they need to be brought to the surface Underground specialized mining equipment such as trucks, loaders, diggers etc are used to excavate the material and are normally hauled toMore Manufacturers and Suppliers of Uranium Mining Equipment Mining Equipment Srinivasa Mining Equipments Suppliers Verified Supplier Srigandada Kavalu, Bengaluru 543, 5th Main Road, 14th Cross, D Druop Layout, Sringandad Kaval, Srigandada Kavalu, Bengaluru , Dist Bengaluru, KarnatakaUranium Mining Equipment Manufacturers & Suppliers in India

2021年10月18日· 1 Mining Truck The first equipment for mining is mining truck Surface miners need heavyduty vehicles to transport supplies around the site Large mining trucks, often known as offhighway trucks, come in mechanical and electric drive varieties, with varying degrees of power and environmental friendlinessMining of sulfur from a deposit at the edge of Ijen's crater lake, Indonesia Mining is the extraction of valuable geological materials and minerals from the surface of the EarthMining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory Ores recovered by mining includeMining

Earth miners play a crucial role in the mining industry because these machines are designed to facilitate large mining and earthmoving projects Along with the specialised skills of the operator, pushing material, scooping loose soil, and removing material are done by using earth movers Earth movers work in close tandem with bulldozersThe main difference between what Denison is doing and ISR uranium mining happening elsewhere in the world is the grade of the uranium deposits Globally, ISR uranium mining is typically used for lowgrade uranium deposits (005% U 3 O 8), whereas Denison’s Phoenix deposit averages over 11% U 3 O 8 with most of the deposit at 46% U 3 O 8Nuclear Power Is Green, but What about the Uranium Mines? Yes,

Uranium mining in Arizona has taken place since 1918 Prior to the uranium boom of the late 1940s, uranium in Arizona was a byproduct of vanadium mining of the mineral carnotite California Uranium was discovered in 1954 in the Sierra Nevada of Kern County, along the Kern River about 30 miles (50 km) northeast of BakersfieldTwo mines, thein situ uranium mining equipment distributors Seven uranium mining and milling companies provided data on occupations in three general groups shaft mine strip mine and processing plant Wyoming has proven reserves of 308 million tons more » of ore or 216 5000 tons of U/sub 3/O/sub 8/ which amounts to about 32 of the proven US reserves at aequipment and machinery utilized in uranium mining

2023年11月28日· The Uranium Mining Process Uranium mining typically involves the extraction of uranium ore from the Earth’s crust, followed by processing to obtain uranium concentrates, known as yellowcake The most common mining methods are openpit and underground mining, each with its own set of environmental challengesUranium mining and milling produces very large amounts of waste, primarily in the form of excavated rock, ores that contain too little uranium to be profitable and mill tailings Mill tailings are produced during the processing of uranium ore They are sandlike, crushed rock residues, which are left over after the uranium has been extractedFact sheet: uranium mining and milling

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityAs with other types of hard rock mining, there are several extraction methods In the case of uranium mining, it strongly depends on the concentration of uranium in the ore For example, the ore extracted from the Australian Olympic Dam Mine has a concentration of 005 %, and most reserves have uranium with a concentration of between 01 bis 02 %Methods and Techniques of Uranium Mining | nuclearpower

2021年7月26日· In situ leaching (ISL) uranium mining technology is an in situ mining technology in which the chemical solution is injected into the orebearing strata through drilling wells, and the solution moves along the ore bed by controlling the hydraulic gradient of the flow field and reacts with the ore to form uraniumbearing solution To reduce2017年9月26日· Environmental Impact One advantage uranium mining has over production methods used to retrieve fossil fuels is that plants need much less uranium to create electricity than is required if using coal, natural gas or oil One kilogram of uranium provides the same amount of energy as about 100,000 kilos of oil or nearly 220,000 kilosWhat Are the Benefits of Uranium Mining? | Sciencing

2018年7月30日· The demand for uranium mining and men to work those mines skyrocketed in the early days of the Manhattan Project, and would become one of its enduring legacies Uranium Mining Uranium mining began on a large scale in the Czech Republic in the late 19th century as a way to procure ores for use in Marie Curie’sKazakhstan has 15% of the world's uranium, and in 2011, Kazakhstan was responsible for 35% of world production There are 17 uranium mines in the country, however, maximum output is capped at 20,000 tons per year [3] Currently, 50 deposits are located in six provinces The responsibility for uranium exploration falls upon two subsidiaryUranium mining in Kazakhstan

You've already forked 2023 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityDescription This Safety Report has been developed as part of the IAEA programme on occupational radiation protection to provide for the application of its safety standards in implementing a graded approach to the protection of workers against exposures associated with uranium mining and processing The publication describes the methods ofOccupational Radiation Protection in the Uranium Mining and