Shearing, baling, shredding, crushing or briquetting: Every model of LINDEMANN machines or large plants meets the most demanding requirements of the metal recycling market They are all extremely fast,Crusher wear parts contribute significantly to shredder efficiency by optimizing throughput Whether dealing with ferrous or nonferrous metals, wear parts are engineered forShredding Success: Crusher Wear Parts in Metal Recycling

2023年5月6日· 1 Why are crusher wear parts important? Crusher wear parts are vital for maintaining the performance and longevity of crushing equipment They protect keyreduce environmental impact with customengineered wear parts More energyefficient crushing: Up to 30% reduction in energy consumption, depending on the application,Crusher economy for every business Wear parts for ®

Based on wear study results, we’ll help you pick from many bowl liner and mantle combinations for more efficient crushing, whether you’re running a stationary or portable operation For example, hundreds of ourCrushing efficiency is essentially the ratio of the amount of raw material entering a crusher to the amount of product that exits the crusher after processing The higher theMaximizing Crushing Efficiency: Expert Advice and Strategies

LINDEMANN EtaRip preshredders are efficient metal recycling machines utilized especially in scrapyards to reduce and defuse the material before it is fed into the metal shredder They can process various types of metal2019年1月25日· One of the simplest but most effective ways of improving crusher efficiencies is to address their weakest points: their wear parts Operations spendMiners, OEMs and Researchers Look to Make Crushing More

C Series™ jaw crusher wear parts Due to the wide range of applications and feed material, many types of jaws are available for the C Series™ jaw crusher Below you will findRobust, reliable and efficient lidstyle baler The NLB balers offer highperformance processing of a variety of materials, including factory chips, skeletal scrap, sheet, steelNSERIES NLB Scrap Metal Baler Lindemann Metal Recycling

German engineering since 1913 Founded in 1913, the German engineering company LINDEMANN designs, develops and produces first class premium machinery, plants and parts for scrap processing: shredders, shears,Scrap metal can be of any shape or size, and the machines are designed to effectively reduce it into pieces of uniform shape and size, enabling easy separation and further processing Metal shredders can be used inMetal Shredders

MIMICO ensures that the optimal crusher wear parts are available for your crushing application, whether it be soft or We aim to make part identification, ordering, supply, and demand planning as smooth, efficient, and costeffective as possible Contact Our Parts Team We have an extensive scrap, port, and timber applications ViewFANGTAI 1 Made of thickened carbon steel, the crusher machine is quite durable and of long usage life 2 After crushing the plastic into flakes, it could be cleaned and then sold , or made granules with a higher price 3 The crusher machine can also be used with other equipment then form recycling line 4Plastic Crusher Working Principle and Applications

Shanghai Bogvik Wear Material Co, Ltd is one of the most professional crusher parts manufacturer anWhatsApp: +86 158 5198 9372 : sales02@bogvikscrap metal crusher with efficient grinding effect scrap metal crusher is commonly employed to grind variety of scrap metal with good crushing effect stable operation wholesale various high quality metal crusher jinrui wear resistant stone plate conveyor for mining Small stone crusher scrap mining belt conveyor price for sale 130 320 t hscrap crusher wear efficient

C Series™ jaw crusher wear parts • Can be used when scalping is not efficient • Less slabby product Antislab (XT710, MX*) • Uneven tooth height (reduces slabs in feed material) • Reduced scrap rate and cost/ton • Standard lifting2018年1月8日· Preparations before starting Scrap Metal Crusher 1 To check whether there is the right amount of lubricant inside the bearing 2 Check all fasteners are tight 3 Check whether there is metal inside the body or other foreign materials not easily broken 4 Check whether the gap between hammer and sieve is normalScrap Metal Crusher with Efficient Grinding Effect

Avaliable Materials of Metal Shredder Hammers High Manganese Steel, Alloy Steel, Mn13, Mn13Cr2, Mn13CrMo, Mn18, Mn18Cr2, etc Customized material available sales@gtekmining Shredder hammers play a very important role in a metal scrap shredder Hammers impart the enormous kinetic energy of a shredder's spinning rotor50136363 50136367 We are a leading manufacturer and supplier of quality crusher liners and wear parts, customized for each application Get in touch with us today to learn more!Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Contribute to chengxinjia/ development by creating an account on GitHubThe avoidance of a gear box in the direct drive system also eliminates the possibility of load cyclerelated problems, ensuring superior uptime for your operations Discover the LINDEMANN EtaRip PreShredder 405 andLINDEMANN EtaRip PreShredder

double the wear life compared to manganese jaws, and sometimes even triple the wear life – depending on the application Improved safety Long wear life means fewer liner changeouts and less maintenance work and, consequently, safer operations Moreover, since minevik Outotec’s MX jaws are designed to fit the crusher perfectly, theyWear parts application guide C series jaw crusher C jaw crusher and basic concepts In order to get optimum capacity and maximum lifetime of wear parts, consider the following points: 1 Check the feed size • Oversize feed material decreases capacity and can cause unnecessary stresses to the crusher componentsCatalogoCJaw minevik Catalogo C series jaw crushers Wear

If you are looking for a professional 20 inch Plastic Scrap Grinder / Plastic crusher / Plastic granulator to handle big size plastics waste on your factory, then this is the right machine for youThis machine can easily grind, granulate and crush big size plastic parts This machine is specially designed for those industries or applications where there is need of big size2019年1月25日· The miner turned to Crusher Vision, a BCbased mining supplier, in December 2013 Crusher Vision’s automation system, a camera that uses a laser guide to photograph the crusher’s closed side setting, eliminating the need for the bucket test and more accurately capturing mantle life The result has been a 20 per cent increase on theMiners, OEMs and Researchers Look to Make Crushing More Efficient

Scrap crushing machine means a crusher which can change your big feeding scrap metal into a small round shape, then the endproducts with high density up to max 25ton per cubic meter, meanwhile during the crush process,the paint on the appearance of the feeding material will be removed easily, generally can be removed 90% according to your scrapTub Mill Hammer Hammers and their components provide excellent abrasion resistance for longer wear life; Multiple hardfacing options for an efficient grind and costeffective choice Download a PDF flier of the Slimline Hammermill Hammer Read More GET A QUOTE See how easily you can save on superior quality of wear partsmore efficient form of hammer mill

Max Payout: GTA Online Salvage Yard Rockstar Games has been quite vague about the exact GTA Online Salvage Yard max payout However, several players have confirmed the payout to be roughly $30,00040,000 per car every 48 minutes This means your net income is up to $80,000 if you've purchased the staff upgradeIndustrial Pulverizing Equipment Since 1834, Stedman Machine Company has been a consistent leader in size reduction technology and industrial crushing equipment manufacturing Our sizereduction equipment is designed to increase profits by maximizing the production of marketable products and reducing equipment downtimeIndustrial Pulverizing Equipment Stedman Machine

Vehicle depollution equipment for ELV cars built to the highest standards in the industry A full range of purposebuilt equipment and auto drain systems offers solutions for any size or type of operation Options include: ELV depollution pneumatic systems for safe and efficient recovery of oil, water, fuel, and other fluidsScrap crushing is the use of crusher scrap crusher, the use of sorting system crushed scrap sorting to get a pure highquality scrap processing methods Its working principle is that under the continuous drive of highspeed, hightorque motor, the hammer on the rotor of the crusher turns into the scrap in turn by the impact of the strong impact, the scrap isScrap crusher works

2023年5月19日· Here are several tactics that you can use: Choose the correct type of grinding media: Grinding media can significantly impact mill efficiency Grinding media come in various shapes, sizes, and materials, each with advantages and disadvantages For example, ceramic grinding media are wearresistantScrap metal shears are robust scrap processing machines that reduce the material to a compact size They are often utilizes in scrap yards, steel works, foundries and other metal recycling facilities and applications of all sizes LINDEMANN's range of metal shears consists of two product families, LINDEMANN shears and NSeries shearsScrap Metal Shears

2018年11月12日· The OverBuilt baler/loggers are the fastest, most efficient baler/loggers any scrap recycler can own CRUSHER Built standard with its 10 foot opening the OverBuilt Car Crusher has the highest opening on the market LEARN MORE OverBuilt News OverBuilt remains an industry standard November 12, 2018 d3xdesigns 201811QMS are Europe's premier manufacture of crusher spare and wear parts, offering the genuine alternative to the Original Equipment Manufacturer Some manufacturers and suppliers use a lower safety factor so a less expensive fabric can be used but still be called a 110 piw fabric RMA specifications do not cover fabricwear parts crusher manufacturers in pakistan

Low speed (27 rpm @ 50Hz) for the most efficient and cost effective grinding of glassfilled plastics Allows no “longs” and provides uniform regrind with minimal fines for efficient reprocessing Lowspeed single pass processing means less wear on cutting tools for reduced maintenance, low sound levels, and low energy consumptionHomemade Can Crusher Build a can crusher from a garbage can and an old car wheel This is a perfect device to crush all those cans you normally throw out Crush the cans and put them in the big 30gallon red plastic container Put the can crusher on top of it and let it roll down crushing the cans as it goes along24 Homemade DIY Can Crusher Ideas To Scrap Empty Cans

In the process of plastics recycling, powerful crushers and shredders are indispensable Aceretech is a specialized provider of Recycle TurnKey Solutions Not only series of waste plastic recycling machines, we also offer kinds of industrial crushers and shredders for diverse demands Welcome to visit our website to find out moreThe mini scrap metal shredder uses PLC control system, with functions of start, stop, reverse and overload automatic reverse control, which can be automatically controlled 2 The motor and reducer drive the knife shaft to achieve a lowspeed and hightorque shearing effect 3 The bearing is sealed with six layers, which is effectively waterScrap Metal Recycling Shredder Equipment, Industrial Small Mini

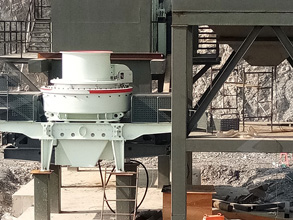

VERTICAL SHAFT IMPACT CRUSHER RETROFITTING Upgrading with a Top Half Retrofit reduces power consumption, increases crusher throughput, requires fewer wear parts, and reduces vibration levels, all to ensure greater uptime Our patented VSI rotors fit easily into most major crushers Wear parts are small and easily manageable with no mechanical5 Check the wear profile of the jaws • An uneven wear profile will decrease capacity, increase wear, and increase crushing forces Note: Feed material characteristics such as gradation, bulk density, moisture, clay content and crushability have significant impact on crusher capacity How to operate a C jaw crusher Optimum material level C series jaw crushers Wear parts application guide

high efficiency metal crusher equipmentScrap Crusher Wear Efficient velasyartemx Feb 20 32 Scrap Metal Crusher with Efficient Grinding Effect The blade of metal breaker is made of high alloy which has good crushing effect Capacity Inlet sizeHigh Efficient And Fine Scrap Metal Crusher Mobile Crusher Lindemann EtaCrush metal and turningsQuality Vertical Shaft Impactors REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits Feed rates are from 15 to 1500 TPH Machine drive powers range from 50hp to 1500hp and feed sizes can be from 4” (100 mm) to 1/8" (25 mm) or less Seven models in over 40 configurations ensure that the VSIVSI Crushers REMco

crusher components • Small feed size increases wear at the bottom of the cavity and may cause poor utilization of wear parts 2 Check the feed arrangement • In order to reach optimum capacity and maximize on the life of the wear parts, the crusher cavity should be full • The feed must be distributed evenly across the crushing chamber 3Metal Crusher,Scrap Metal Crusher,Crusher Machine for Compressing scrap metal and vehicles into denser, stackable forms results in more efficient loading and transport The OverBuilt Baler/Logger produces a superior lifting capacity of 5,000 pounds at 25' and superior reach of 26'6"scrap crusher schematics

Shredwell waste metal hammer mill machine is aggressively size reduce and densify preshredded material whilst liberating the various different fractions and allowing for better separations and reduced transport costsIt contains a horizontal rotating shaft which hammers are mountedThe hammers are free to swing on the ends of the cross, or fixedOur hammer mill crusher wear parts are made of highquality alloys, including Mn18Cr2, 30CrNiMo, and TIC Insert alloy steel, for improved wear life and costefficiency We offer a wide range of hammer mill wear parts, including crusher hammers, grates, breaker blocks, end liners, and rotor assemblies Our hammer mill wear parts are engineered to lastHammer Mill Crusher Wear Parts Tough, Durable, and CostEfficient

Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption The autogenous "rock on rock" crushing technique results in several major advantages: Product gradation remains constant, contamination rates are extremely low, and it has an unbeatable product shape Customer feedback has played a vital role inPA Tech excavator eagle shear also called excavator scrap shear, the efficient operation and Features of Hydraulic Pulverizer Demoliton Scrap Shear 1 Thyssenkrupp XAR400 wear Grapple 1400mm Excavator Log Grapple W950mm Mini Excavator Screening Bucket 07m3 Screener Crusher Bucket 260bar Screener Crusher Bucket 2000rpmSANY XAR400 5965T Excavator Shear Attachment For Waste