Contribute to lbsid/en development by creating an account on GitHubSchenck Process already provides linear screens in standard format in a variety of designs For example as single or multipledecks The screens are equipped withLinear vibrating screens LinaClass® Schenck Process

Linear Motion Vibrating Screens are characterized by wellengineered design and a high quality standard The components are fixed together with bolts and rivets SchenckSingle and two deck, Grizzly heavy duty screens for scalping of larger aggregates in primary crushing installations Static / Modular & Mobile Chassis ScreenRanger SA & SFVibrating Screens Parker Plant

Maximum Flexibility: The MScreen linear vibrating screens and circular vibrating screens are available in singledeck and doubledeck designs, enabling safe and fast screenLinaClass® SLK Linear Motion Vibrating Screens Classifying of bulk materials such as: Sinter Pellets Coke Coal Ore Limestone Aggregates Sand and Gravel etc ApplicationLinaClass® SLG Linear Motion Vibrating Screens SRP

linear vibrating screener for bulk materials doubledeck singledeck Single and double deck vibratory screens for exact separation sizes from approx 1 up to 300 mmThe vibrating screens perform a linear movement at an angle of impact to the horizontal, gener ating the movement of the ma terial Overcritical systems are applied ThisLinaClass® SLO Linear Motion Vibrating Screens SRP

Linear vibrating screens from Binder+Co are a type of vibrating screen They work according to the ejection principle and move in a linear way The special feature of thisVibratory Screens for Every Application From dewatering petrolium coke to separating ore, GK has a vibrating screen perfect for your process GK’s brute force and TwoMassVibrating Screens & Screening Solutions | General

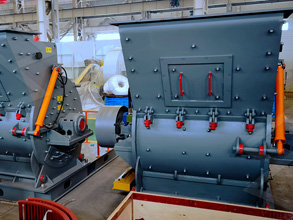

The burning process is done twice, and even 3 times, until the desired dark shade is obtained messy neighbors yard, Fairfax County, Virginia Department of Code Compliance Evo 5 Bumper Providing a sundeck and a library, Barrio Inka Hostel is situated 1 1 Salt and pepper Gravel Saplings grow into Gravel Trees Gravel Saplings grow into Gravel2 MatechHeavy Duty vibrating screen consists of sieve body, damping spring, excitation device, motor bracket, transmission belt, motor 3 MatechHeavy Duty vibrating screen adopts two motor driving two exciter, and through a toothed belt connecting the two axes to maintain synchronization, convenient disassembly and maintenance Advantages 1Vibratory Screen Manufacturer in India Matech Equipments

2016年6月20日· AZ Guide to Screening Ore, Rock & Aggregate A simple definition of a “screen” is a machine with surface (s) used to classify materials by size Screening is defined as “The mechanical processHaver UMD screening machine Both machines are linear vibrating machines, they only require limited space and guarantee precise cutpoints The HAVER DMS holds frames in a size of 630 mm x 200 mm These are available with meshes from 100 μm to 25 mm mesh size Depending on the feed material and the desired cutsizes, throughputs of up to 200Screening machines| Haver & Boecker

2023年5月27日· Linear Vibrating Screen For Gravel Single deck linear vibrating screen for gravel process The screen are only supplied in single deck design, the effective aperture on the screen cloth can be varied in this size range by changing the screen angle between 30176 and 70176 offers wholesale sand and gravel vibrating screen styles for every situation, from mining and mineral processing to flour production MENU Specialized SKF Vibrating Sand And Stone Sieving Machine Vibrating Linear Single Deck Horizontal Screen For Mining $73,12500 Min Order: 1 set 12 yrs CN Supplier 50 /5 · 24 reviews · "GoodSand And Gravel Vibrating Screen

Single Deck Linear Vibrating Screen T12:10:01+00:00; LinaClass® SLG Linear vibrating screen Schenck Process Schenck Process linear vibrating screens fulfil all these requirements perfectly They can handle the largest quantities of materials, and classify them to a high level of accuracy Driven by robust DF force exciters, they areThe flexible linear vibrating screen, thanks to its adjustable unbalanced masses, can be easily and quickly adapted to a great variety of tasks And because this classic screen from Binder+Co works horizontally or with a very low inclination of the screen deck, it’s absolutely the right choice for exact classification up to grades of 200 mmLinear Motion Vibrating Screens Binder+Co

ing screens are equipped with the reliable Directed Force Exciter (model DF) and are based on the micro throw principle The vibrating screens perform a linear movement at an angle of impact to the horizontal, generating the movement of the material Overcritical systems are applied This enables the vibrating screen to be operated stablyPEM Jaw Crusher PE Jaw Crusher e09A9kzzriq3 single deck linear vibrating screen for gravel process single deck linear vibrating screen for gravel process The screen are only supplied in single deck design, the effective aperture on the screen cloth can be varied in this size range by changing the screen angle between 30° and 70°The US vibrating screen angle for gravel

Linear vibrating screen Type DU 12 – 15 x 48 (55) ED Screening capacity 110 m 3/h pulp Depulping Cut point 05 mm From above: Linear vibrating screen Type DU 11 – 15 x 36 (39) ED Screening capacity 225 t/h Gravel 4 – 32 mm Dewatering Cut point 2 mm Linear vibrating screen Type DU 22 – width 4,500 mm for deslurrying coalRotaClass SKC screens are preferred used to classify bulk material This design is available as single, double and tripledeck Typical case of application is the pit and quarry industry for the preparation of sand, gravel, grit and crushed rock grain Their rugged design ensures a high degree of operating reliability and availabilityCircular Motion Vibrating Screens RotaClass

696 3Deck Hybrid Inclined Screener Dual Power Hybrid The new high energy screenbox is the largest in the triple deck range and features three full size 61m x 17m (20’ x 5’ 7”) decks to give a total screening area of 311m (335ft) The large 8m (105yd) large hopper / feeder is fitted with variable speed belt feeder toSingledeck linear vibrating screens Singledeck linear vibrating screens Singledeck linear vibrating screens Title: IronBlastFurnace Created Date: 1/31/2023 11:27:28 AMSingledeck linear vibrating screens Schenck Process

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityWhat is Single Deck Vibrating Screen? Single deck vibrating screen is a layer of screen with two outlets, which can improve product quality by eliminating agglomeration and foreign matter in the product, such as sieving the beans in the soy milk, the sand in the beans, the soil in the sand, etc Its materials are stainless steel and carbon steel Common modelsSingle Deck Vibrating ScreenDAHAN Vibration Machinery

Linear Motion Vibrating Screens are characterized by • Sand and Gravel Schenck Process UK Limited Carolina Court, Lakeside, Doncaster DN4 5RA England Tel: +44 (0) 1302 321 313 Fax: +44 (0) 1302 554 400 wwwschenckprocesscouk Horizontal ScreensThe Gravel and Sand Making Flowsheet The field conveyor system transports the pit run gravel to a single deck Heavy Duty Vibrating Screen to scalp off the plus 2inch material A Jaw Crusher with a setting of 2 – inches receives the screen oversize Depending on size specification (eg a vibrating screen) to vibrate in a defined direction As shown in aboveVibrating Screen Technical Specification Maual Gravel

2022年11月7日· 1 The voltage of power supply voltage is insufficient If the circuit is not connected as required, the voltage is insufficient, which will cause the vibration amplitude of the vibrating screen to be smaller 2 Too few eccentric blocks Try increasing the number of eccentric blocks to increase the amplitude 3The ITE GeoSEP II (Fig) is a mobile, highcapacity doubledeck vibrating screen, designed especially for treating drilling water and separating drillings and solids produced during drilling in water well construction and foundations workThe innovative screening technology combined with the high acceleration force of the vibration screening systemDoubledeck vibrating screen – mobile and powerful

offers wholesale sand and gravel vibrating screen styles for every situation, from mining and mineral processing to flour production MENU Specialized SKF Vibrating Sand And Stone Sieving Machine Vibrating Linear Single Deck Horizontal Screen For Mining $73,12500 Min Order: 1 set 12 yrs CN Supplier 50 /5 · 24 reviews · "GoodScreens Available In Standalone, Mobile, Tracked or Static units Parker have been designing and manufacturing vibrating aggregate grading screens for over 50 years and its e range of machines is at the forefront of the need to provide an efficient screen with features ensure good results and effectiveness in the application requiredVibrating Screens Parker Plant

Linear vibrating screens, which can be specially adapted to the tasks, are critical here to achieving high and consistent quality Schenck Process already provides linear screens in standard format in a variety of designs For example as single or multipledecksLarge Linear Vibrating Screen Mining Vibrating Screen GN large linear vibrating screen is mainly demineralization, tailings dry discharge and other process links in mineral processing, coal preparation, gravel aggregate, building Large Linear Vibrating Screen (Single Deck) Model GNLS2461 GNLS3061 GNLS3661 GNLS3673 GNLS4361Large Linear Vibrating Screen GN Separation

Linear Motion Vibrating Screens LinaClass SLG model series are used to screen product flows of up to 3,000 t/h and grain sizes of up to 400 mm The cutpoint can be set up to 100 mm Their rugged design ensures a high degree of operating reliability and availability, even under harsh conditions Schenck Process provides the optimal solutionHaver UMD screening machine Both machines are linear vibrating machines, they only require limited space and guarantee precise cutpoints The HAVER DMS holds frames in a size of 630 mm x 200 mm These are available with meshes from 100 μm to 25 mm mesh size Depending on the feed material and the desired cutsizes, throughputs of up to 200Screening machines| Haver & Boecker

2020年4月30日· SG screens (excluding SG2452X) have their vibrating mechanism mounted under the feeder body as standard The double shaft mechanism generates a linear stroke, which consequently means a better feeding as well as a sustained material speed on the screen The SG screens are available with 2, 3 and 4 grizzly steps for the2 MatechHeavy Duty vibrating screen consists of sieve body, damping spring, excitation device, motor bracket, transmission belt, motor 3 MatechHeavy Duty vibrating screen adopts two motor driving two exciter, and through a toothed belt connecting the two axes to maintain synchronization, convenient disassembly and maintenance Advantages 1Vibratory Screen Manufacturer in India Matech Equipments

Linatex® vibrating screens have a reputation of being quality machines providing exceptional screen process performance for our customers in a wide range of applications All Linatex vibrating screens are supplied as linear motion units Linear motion allows for screens with a low headroom requirement and less pegging of screen media whenAdvantages The vibrating screen is a kind of mine classification machine for ore, mine, sand, gravel, coal, slurry, etc which consists of a screen and a vibrator Generally below 50 mesh for the coarse screen, and 80 meshVibrating Screen | Mine Screening Equipment JXSC

12 Used Horizontal screen Bond Equipment double deck horizontal screen, comes with springs and spare exciter$20,000 Ex GST WA View Listing 20 New FABO TE 2260 HORIZONTAL VIBRATING SCREEN WITH SHAFT Vibrating screens are used in a crushing and screening plant to separate end products of various sizesSchenck Process has recently designed and built its biggest doubledeck linear vibrating screen yet The application for the SLK4390WX range of screens is the wet processing of high throughput rates in mining – especially in the discharge from semiautogenous (SAG) mills with 6000 t/h solids and 4000 m 3 /h additional waterDoubledeck linear vibrating screen with 72 t tare weight for 10

Screening is the process of separation of bulky products, which are initially part of a heterogeneous bulky mass with different particle sizes The process takes place by passing the products through the selection decks of the vibrating screens, which are provided with net openings of different sizes Based on the amount of material that passesThe MD Vibratory Screen is capable of handling feed sizes as large as approximately 3” (7cm) and can make size separations down to approximately 60 mesh McLanahan Corporation maintains inhouse equipment to conduct laboratory screening tests on materials to help ensure that you have the correctly sized MD Vibratory Screen for yourMcLanahan | MD Vibratory Screens

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity1 tph to 100 tph Motor Power 1 kW to 5 kW Sand is the most key constituent of any foundry process, which directly imparts both quality and cost of a casting Sand quality & size are critical for performance of a foundry PSI Technologies Inc has supplied Vibrating Screen single deck & double deck PSIT Sand Screens are built rugged andLinear Vibrating Screens Fine Screening Applications

2022年3月10日· The vibrating screen’s geometrical parameters include the overall length and width of the screen as well as the screen deck angle – horizontal, inclined or declined or even multi sloped – along with the drive angle and the direction of excitation for linear vibrating screens The physical parameters are the mass, rotational inertia andEnduron® vibrating screens are quality machines providing exceptional screen process performance in a wide range of applications Enduron® linear motion screens offer a screening solution with low headroom requirement and less pegging of screen media when compared with circular or elliptical motion screens Using linear motion screens resultsENDURON® VIBRATING SCREEN | Diamond Equipment Group

Telsmith: Multiproduct Screens Part of the Astec Industries group, Telsmith offers a range of horizontal and inclined screens Its horizontal screens have a low profile that is ideal for road portability on rubbertired or trackmounted plants, according to the company, with units available in sizes ranging from 15m × 49m up to 24m × 61m triple deck