2013年1月1日· In this paper, a dynamic crushing plant simulator implemented in MATLAB/SIMULINK has been connected to a WebHMI The WebHMI is accessible viaThe operation of a crushing plant is complex and suffers variabilities during the process operation, resulting in a drive for optimization functionality development ProcessOptimization Capabilities for Crushing Plants Chalmers

In this paper a dynamic crushing plant simulator implemented in MATLAB/SIMULINK has been connected to an HMI via a PLC The HMI is placed in a control room at theMedia Kit Optimizing Crusher Control June 2014 | Features Big benefits can be won by controlling a crushing plant carefully (Photo courtesy of Sandvik) Crushers are energyOptimizing Crusher Control | E & MJ

2020年6月2日· This Control Room is the Master Control Station (MSC) that overlooks the MMD Plant through accessible sloped window The Control Room ships in two (2)2014年9月23日· Latestgeneration control of a complete crushing and screening plant can now readily be conducted remotely from a centralized control room or weighbridgeIntelligent Control and Monitoring of Feed Into Crushing and

The control room is where operators perform plant operations using control systems every day, and a safe, comfortable, and functional environment helps operators to run the2015年10月15日· The dynamic simulation approach as demonstrated by Asbjörnsson [3] is applied process modeling of the crushing plant The simulation can capture operational(PDF) Crushing Plant Dynamics ResearchGate

WRT Crushing Plant control van features two rooms: motor control room and generator room Offerings include: Tandem or triple axle 8' 6" x 53' highway van 6' x 10' control2023年10月8日· Kesimpulan Dari artikel diatas kita telah mempelajari halhal terkait dengan apa itu crushing plant, bagaimana proses kerjanya, manfaatnya, berikut dengan tantangan dalam penggunaanya Dapat disimpulkan bahwa crushing plant adalah aset berharga bagi industri pertambangan, memainkan peran sentral dalam mengubahApa Itu Crushing Plant dan Bagaimana Peranannya Dalam

Crusher Plant Control Room In Singapore elrus stationary control towers feature 30” locking steel door with 18” window full 360o view of the crushing spread climate control for Control Room Of A Crushing Plant2020年6月2日· • Tower and Platform for the Control Room • Tower and Platform for a Rock Breaker (rock breaker not included in this package) • 2 Davit Cranes • Spare Parts including Gearboxes, Motors and MORE ID 18CAR03ID MMD ROCK CRUSHING PLANT Rabin Worldwide

• Fully electric plant • Dismantle, pack, and setup on new site in 24 hours • Easy to tow by a standard truck • Automation as a standard Bestinclass performance Easy to setup Fast overseas delivery 4 1 Step How many 4 5A welldesigned plant layout balances the capital versus operating cost over mine life Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possibleCrushing Plant Design and Layout Yeco Machinery

2017年10月26日· APPLICATION EXAMPLE: Remote control of mobile screening and crushing plant using Machine Remote Control THOR B3 remote transmitter and Imet HDC receiver skip to Main Content +61 2 年2月24日· Crusher: The crusher is the main component of the mobile crushing plant It crushes the material into smaller pieces, reducing them to a size that can be transported by conveyors or other means Conveyor: The conveyor is used to transport the crushed material to a designated area for further processing or stockpilingA Guide to Mobile Crushing Plants: Types, Components

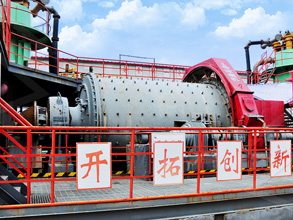

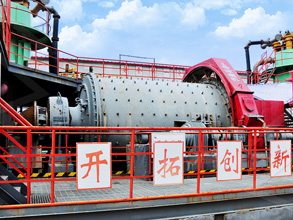

Experiences in minerals processing plant treatments with crushing(jaw crusher ,cone crusher and convoying system)<br>Sag mill, ball mill, Vertical Mill cyclones,cil ,tail ,cip,theckening monitoring and management,elution and electrowinnings monitoring<br>Falcon avec gravimetrie et le systeme du gekkoDeep knowledges and2013年1月1日· In this paper, a dynamic crushing plant simulator implemented in MATLAB/SIMULINK has been connected to a WebHMI The WebHMI is accessible via the Internet, thus creating a realistic control room for operators’ training In the created training environment, the operators can be trained under realistic conditionsAn OnLine Training Simulator Built on Dynamic Simulations

2015年10月15日· The dynamic simulation approach as demonstrated by Asbjörnsson [3] is applied process modeling of the crushing plant The simulation can capture operational behaviors, for example, material delay2022年5月5日· DMSFOG is an effective dust control solution that uses smart dry fog and fine mist systems Dust suppression systems in DMSFOG consist of stainless nozzles that can produce either fog or mist Using microscopic amounts of water, the system covers the source of dust andHow do you control dust in a crushing plant?

2023年6月3日· Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, and safe operation of ore crushing and screening In the practice of production, the crushing and screening process is related to the particle size of raw ore,2019年10月15日· InterConnecting Automation, an AutomationDirect system integrator, helps inhouse staff to upgrade an aging and highly manual control system into a modern and easytoconfigure design Todd Timpa CTC Crushing process overview Figure 1: The surface mine at the topModern controls, system integrator automate rock

2014年9月23日· Latestgeneration control of a complete crushing and screening plant can now readily be conducted remotely from a centralized control room or weighbridge office at a quarry, including any or all of the primary, secondary andIn a second example, Sandvik describes a case where an operator has several CH870 crushers with ASRi and WINi installed, allowing crushing to be operated from a control room The same operator also has some bowltypeOptimizing Crusher Control | E & MJ

2016年8月11日· Therefore, when there is failure in one of the processing machines it can be simply controlled from the computer at Crushing Plant control room After passing through a size reducing process by using Crushing Plant equipment the2019年5月14日· Dust collection in the crushing plant is accomplished by two wet dust collectors with a total of 66,000 CFM The dust collectors exhaust air is discharged to the upper ventilation system of the mine through an 800 ft vertical raise and then through mine fans to the surface The screening area exhaust system has exhaust hoods with 1500Dust Collection and Control in Crusher Plant 911 Metallurgist

2023年2月23日· When designing an aggregate crushing plant, there are several factors that must be taken into account to ensure that the plant meets the desired performance and output goals These factors include: Type of material being crushed: The type of material being processed will have a significant impact on the design of the crushing plant2020年2月3日· 00 Limestone Quarry and Crushing Plant The major raw material for cement production is limestone The limestone most suitable for cement production must have some ingredients in specified quantities ie, calcium carbonates, silica, alumina, iron, etc Typically, cement plant locations are based upon the availability of good qualityBASIC CEMENT PLANT LAYOUT The Cement Institute Forum

2017年6月23日· About the Author: Kevin Yanik Kevin Yanik is editorinchief of Pit & Quarry He can be reached at 2167063724 or A stateoftheart plant at Inland Aggregates consuming less water, electricity and fuel steers a Canadian operation into a new phaseNomore, is an Experienced Field and Control Room Operator, a resultsdriven personI have vast knowledge and experience on Dense Medium Separation, Crushing and Screening, Recovery, XRT Machines and Scada operation | Learn more about Nomore Mugwagwa's work experience, education, connections & more by visiting their profile onNomore Mugwagwa Process Plant Operator LinkedIn

Crushing plant control room automation, is the new crushing plant control, with scalable DNA automation systems that adapt to the diverse Rock crushing plants; The name for the new company was sought in an2007年2月1日· The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust Remedies to this problem include the retrofitting of shrouds, enclosures, local exhaust ventilation (LEV) systems and water suppression systems The single or combined application of theseImproved dust capture methods for crushing plant ScienceDirect

The control room is where operators perform plant operations using control systems every day, and a safe, comfortable, and functional environment helps operators to run the plant more efficiently The control room must therefore be designed accordingly Yokogawa has been designing control rooms for various industries for over 30 years1 Notify the control room that the primary crushing area preoperational inspection for a pending startup is about to begin Advise the mine of the time that the start of crusher operation is scheduled or anticipated General AreaSTANDARD OPERATING PROCEDURE PRIMARY

2022年1月28日· OF EXPERIENCE AT YOUR SERVICE 39 0464 Viale Caproni 11 / E38060 Rovereto (TN) QAUTOMATION is Maestro's automated control system that brings your crushing plant to its maximum potential5 天之前· 60tph stone crushing plant for recycling construction wastes APS1548Y3 vibrating screen APC900Y compound cone crusher APG0724Z vibrating feeder APJ4060E jaw crusher Max feeding size: 400mm Finished particle size: screen size is 4800*1500mm Yield demands: 60 ton per hour Configurations: APG0724Z (vibratingStone Crusher Plants Transform Stones Into Valuable

2014年4月1日· Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions Above 1000 tph, primary gyratory crushers are an option After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layoutCarroll Training Services (RTO#45753) offers the nationally recognised RIIPRO301D – Conduct crushing and screening plant operations unit of competency with high quality course materials and premier student support We deliver training that is customised to meet the needs of our students and employersRIIPRO301D Conduct crushing and screening plant operations

2023年2月23日· One of the key benefits of a 300 tph crusher plant is its impressive capacity With a crushing capacity of up to 300 tonnes per hour, it is capable of handling even the largest of jobs with ease Additionally, it is equipped with various components, such as a feeder, crusher, conveyor, and control panel, that work together to ensure2021年12月1日· In this paper, a dynamic crushing plant simulator implemented in MATLAB/SIMULINK has been connected to a WebHMI The WebHMI is accessible via the Internet, thus creating a realistic control roomAutomated process control system of Jaw crusher production

2020年7月12日· Crushing of flux is most widely used for preparing the raw material for sintering process, because of its higher production and high control of final products In the highly competitive world, it is very much important to keepA crusher is a machine designed to reduce large Coal into smaller Coals, gravel, or rock dust crushers are machines which use a metal surface to break or compress materials Mining operations use crushers, commonly Figure 1: Coal Handling Plant 451 Int J Mech Eng & Rob Res 2013 Girja Lodhi, 2013OPERATION AND MAINTENANCE OF CRUSHER HOUSE

Here, we review the cone crusher literature, focusing on the modeling and control of crushing circuits A total of 61 works published in the primary literature, ranging from 1972 to 2020, are2023年2月28日· Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding ofThe Complete Guide to Primary Crushing, Secondary

3 With more than 2,000 plants in over 65 countries on 4 continents, Meka is helping to build a better world 30 YEARS IN THE AGGREGATE AND CONCRETE PRODUCTION INDUSTRY Meka was founded in 1987 in Ankara, Turkey2016年4月14日· Crushing & Screening Plant Design Factors Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a veryCrushing & Screening Plant Design Factors 911 Metallurgist

A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations Crushing plants may be either fixed or mobile A crushing plant has different stations (primary, secondary, tertiary,) where different crushing, selection and transport cycles2014年5月14日· Relevant use of KPIs both for equipment and processes can be useful here to enable the decisionmaking process for the operators and plant managers Yilmaz (2014) investigated performance aspectsField monitoring and performance evaluation of crushing plant

2023年8月7日· The crushing and screening plant is available in either of mobile, portable and skidmounted configurations, with a capacity of 50600 tons per hour, and final products of 070mm Limited variation to our standardized designs according to well defined, engineering sets of customer requirements may be made available, provided all product